Wire Woes Begone! Master Drawing Machine Loading Now!

Wire drawing, a critical process in the manufacturing of various metal products, relies heavily on the efficiency of drawing machines. Proper understanding of roller alignment, an essential attribute of drawing machines, is a key element in avoiding common production delays. SKET Steels, a leading organization specializing in wire manufacturing equipment, emphasizes the importance of correct loading procedures to prevent damage to both the machinery and the wire itself. Ensuring that operators utilize lubricants correctly to reduce friction is vital to achieving optimal outcomes. This article details the right way of putting wire in the rollers in a drawing machine, a procedure often refined with the help of tools like a feeler gauge, guaranteeing smooth operation and high-quality wire production.

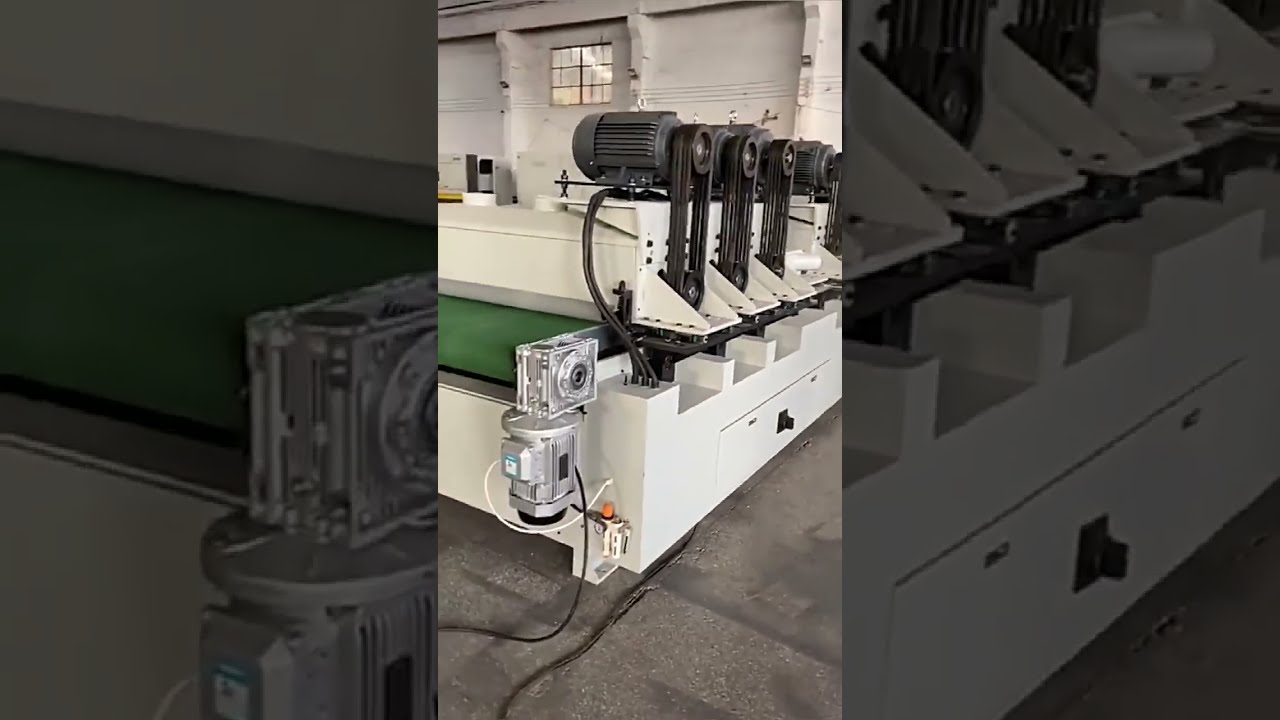

Image taken from the YouTube channel SAMACH Woodworking , from the video titled Woodworking Wire Drawing Machine .

Wire Woes Begone! Mastering Drawing Machine Loading

This guide aims to provide a clear and concise explanation of the correct method for loading wire into the rollers of a drawing machine, ensuring smooth operation and preventing damage to both the machine and the wire. Understanding the right way of putting wire in the rollers in a drawing machine is crucial for efficient wire drawing.

Understanding the Drawing Machine and Its Rollers

Before delving into the loading process, it’s beneficial to understand the function of the drawing machine and the role of its rollers.

The Purpose of a Drawing Machine

A wire drawing machine reduces the diameter of wire by pulling it through a series of dies. These dies are often lubricated to minimize friction and heat. The machine typically consists of multiple blocks, each with its own die and set of rollers.

The Function of Rollers

The rollers play a crucial role in the wire drawing process. They perform several key functions:

- Pulling the Wire: The rollers grip the wire and pull it through the die.

- Maintaining Tension: They maintain consistent tension on the wire, ensuring uniform reduction in diameter.

- Cooling the Wire: Some rollers are designed to help cool the wire as it passes through the machine.

The Right Way of Putting Wire in the Rollers in a Drawing Machine

Proper loading of the wire into the rollers is essential for the efficient and safe operation of the drawing machine. The process involves careful alignment, proper tension, and adherence to specific loading sequences.

Step-by-Step Loading Procedure

-

Preparation:

- Ensure the machine is powered off and disconnected from the power source.

- Thoroughly clean the rollers and dies. Remove any debris or buildup from previous operations.

- Verify that the wire to be drawn is free of kinks, bends, or other imperfections. These can cause problems during the drawing process.

-

Initial Positioning:

- Start by feeding the wire through the first die.

- Gently guide the wire between the first set of rollers. Refer to the machine’s diagram or manual for the correct roller configuration.

-

Roller Engagement:

-

Type 1: Pressure Rollers: For machines with pressure rollers, ensure the pressure is properly adjusted. Too much pressure can damage the wire, while too little can cause slippage.

-

Type 2: Grooved Rollers: For machines with grooved rollers, ensure the wire sits correctly within the groove. Misalignment can lead to uneven drawing and potential wire breakage.

-

Important Considerations:

- Always consult the machine’s manual for the recommended pressure or groove selection.

- Visually inspect the wire after each roller engagement to confirm proper alignment.

-

-

Progressive Loading:

- Continue threading the wire through the subsequent dies and rollers, one block at a time.

- Maintain consistent tension on the wire as you proceed.

-

Final Securing:

- Once the wire has passed through all the dies and rollers, secure the end of the wire to the take-up spool or coiler.

Visual Aid: Roller Configurations (Example)

| Roller Type | Description | Diagram (Conceptual) |

|---|---|---|

| Pressure Rollers | Rollers that apply pressure to the wire, often adjustable. | (Imagine a simple diagram here) |

| Grooved Rollers | Rollers with grooves that guide the wire, preventing lateral movement. | (Imagine a simple diagram here) |

| Combined Rollers | A combination of pressure and grooved rollers for enhanced grip and guidance. | (Imagine a simple diagram here) |

Note: Refer to your specific machine’s manual for accurate diagrams and specifications.

Troubleshooting Common Loading Issues

Even with careful loading, problems can sometimes arise. Here’s how to address some common issues:

Wire Slippage

- Cause: Insufficient roller pressure or worn rollers.

- Solution: Increase roller pressure (if adjustable) or replace worn rollers.

- Additional Tips: Consider using a roller cleaner to improve grip.

Wire Breakage

- Cause: Excessive tension, sharp bends in the wire, or damaged dies.

- Solution: Reduce tension, remove any kinks or bends, and inspect the dies for damage.

- Additional Tips: Use proper lubrication to reduce friction and heat.

Uneven Drawing

- Cause: Misaligned rollers or inconsistent wire tension.

- Solution: Ensure proper roller alignment and maintain consistent wire tension throughout the drawing process.

- Additional Tips: Regularly check the machine’s calibration and alignment.

By following these guidelines, you can significantly improve the efficiency and safety of your wire drawing operations. Remember to always consult your machine’s manual for specific instructions and safety precautions.

Wire Woes Begone! FAQ: Mastering Your Drawing Machine

Here are some frequently asked questions to help you get the most out of your drawing machine and avoid common wire-related issues.

What’s the biggest reason drawing machines fail?

Improper wire loading is a major culprit. Ensuring the wire is correctly seated in the rollers is crucial for smooth operation and accurate drawings. This means understanding the right way of putting wire in the rollers in a drawing machine.

What kind of wire should I use?

Use wire specifically designed for drawing machines. The correct diameter and material (typically steel or brass) will ensure optimal performance and prevent premature wear on the machine. Using the wrong type can lead to slippage or breakage.

How often should I clean and lubricate the machine’s rollers?

Regular cleaning and lubrication are essential. Dust and debris can interfere with the wire’s grip, while dry rollers increase friction. Clean the rollers with a soft cloth and apply a light lubricant designed for precision machinery, paying attention to the right way of putting wire in the rollers in a drawing machine.

What if the wire keeps slipping or breaking?

Slipping often indicates worn rollers, incorrect wire size, or inadequate tension. Broken wire can result from too much tension, a damaged roller surface, or metal fatigue. Check the rollers for wear and ensure the tension setting is appropriate for the wire type and project, keeping in mind the right way of putting wire in the rollers in a drawing machine.

So, there you have it! Now you know the lowdown on the right way of putting wire in the rollers in a drawing machine. Go forth and conquer those wire woes!