Tensile Shear Force: The Ultimate Guide (You Need to Know)

Understanding tensile shear force is crucial for engineers, material scientists, and anyone involved in structural design. Finite Element Analysis (FEA), a powerful simulation tool, offers the ability to model and predict the behavior of materials under such stress. These tests are often performed according to standards set by organizations such as ASTM International, ensuring consistency and reliability. Material selection significantly influences a component’s resistance to tensile shear force. Therefore, comprehending the underlying principles of tensile shear force is key to safe and effective engineering solutions.

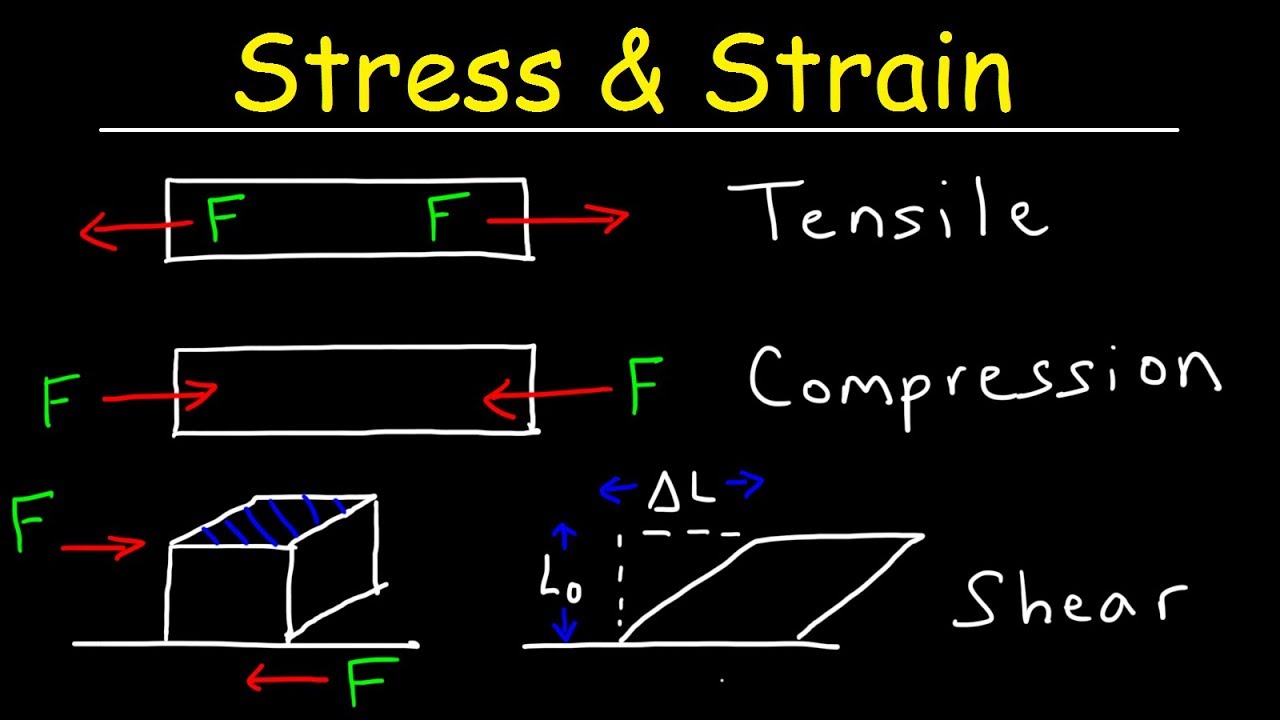

Image taken from the YouTube channel The Organic Chemistry Tutor , from the video titled Tensile Stress & Strain, Compressive Stress & Shear Stress – Basic Introduction .

Structuring "Tensile Shear Force: The Ultimate Guide (You Need to Know)" for Maximum Impact

To deliver a comprehensive and engaging guide on "tensile shear force," the article needs a clear, logical structure that progressively builds understanding. This breakdown provides the ideal layout:

Introduction: Hooking the Reader and Defining Key Terms

- Hook: Start with a relatable scenario where tensile shear force is subtly at play. Think about a poorly glued object falling apart or a weak seam on a fabric tearing. This grabs attention immediately.

- Define Tensile Shear Force: A concise, plain-English definition is crucial. Avoid jargon. Explain that it’s a force acting both to pull apart (tensile) and slide parts past each other (shear) simultaneously. Use a simple diagram or illustration here.

- Distinguish from Pure Tension and Pure Shear: Highlight the combined nature of tensile shear force. Briefly explain how it differs from purely tensile force (pulling directly apart) and purely shear force (sliding motion only).

- Why This Matters: Explain the importance of understanding tensile shear force in various applications, hinting at the sections to come. Emphasize safety, reliability, and efficiency improvements.

Understanding the Components: Tension and Shear

What is Tensile Force?

- Definition: Provide a more in-depth explanation of tensile force as a pulling force that stretches or elongates a material.

- Examples: Real-world examples like a rope pulling a weight, a cable supporting a bridge, or a rubber band being stretched.

- Units of Measurement: Explain the standard units used to measure tensile force (e.g., Newtons, pounds-force).

What is Shear Force?

- Definition: Describe shear force as a force that causes layers of a material to slide past each other.

- Examples: Cutting paper with scissors, pushing a book across a table, or the force on a bolt connecting two plates.

- Units of Measurement: Explain the standard units used to measure shear force (same as tensile force).

How Tensile Shear Force Works: The Combined Effect

- Diagram or Illustration: A visual representation is essential. Show a clear diagram illustrating how both tensile and shear forces act simultaneously on a material. Label the forces and the affected area.

- Breaking Down the Force Vector: If appropriate (and without getting overly technical), explain how tensile shear force can be broken down into its tensile and shear components using vector analysis. Include a visual aid if possible.

- Material Response: Discuss how different materials respond to tensile shear force. Consider materials like:

- Metals: Ductile vs. brittle behavior.

- Adhesives: Bond strength, peel strength.

- Wood: Grain orientation effects.

- Composites: Layer interaction.

Factors Influencing Tensile Shear Strength

- Material Properties:

- Tensile Strength: A brief explanation.

- Shear Strength: A brief explanation.

- Elasticity and Plasticity: How these properties affect the material’s ability to withstand the force.

- Geometry of the Joint/Component:

- Contact Area: How the size and shape of the contact area influence strength.

- Stress Concentrations: Explain how sharp corners or holes can create stress concentrations and weaken the joint.

- Angle of Applied Force: How the angle at which the force is applied affects the relative contributions of tensile and shear forces.

- Environmental Conditions:

- Temperature: How temperature changes can affect material properties and joint strength.

- Humidity: The effect of moisture on adhesives and certain materials.

- Corrosion: How corrosion can weaken materials and joints.

Practical Applications of Tensile Shear Force Analysis

Use specific and varied examples to illustrate the real-world relevance:

- Adhesive Bonding:

- Analyze how tensile shear force affects the bond strength of adhesives in various applications (e.g., automotive assembly, electronics manufacturing).

- Consider different types of adhesives and their resistance to tensile shear.

- Mechanical Fasteners (Bolts, Rivets, Screws):

- Explain how these fasteners are used to resist tensile shear forces in structural connections.

- Discuss the importance of proper fastener selection and installation to ensure joint integrity. Include a table showcasing the shear strength of various bolt sizes.

- Welding:

- Explain how welding creates a strong bond that can resist tensile shear forces.

- Discuss different welding techniques and their suitability for different materials and applications.

- Textile and Fabric Manufacturing:

- Describe how seams in clothing and other fabric products are subjected to tensile shear forces.

- Explain the importance of strong seams and proper stitching techniques to prevent tearing.

- Civil Engineering (Bridges, Buildings):

- Explain how tensile shear forces act on structural elements in bridges and buildings.

- Discuss the role of engineers in designing structures that can withstand these forces.

Testing and Measurement of Tensile Shear Force

- Tensile Shear Testing Methods:

- Lap Shear Test: Explain the procedure and its applications. Include an image or diagram.

- Single Shear Test: Explain the procedure and its applications. Include an image or diagram.

- Double Shear Test: Explain the procedure and its applications. Include an image or diagram.

- Equipment Used: Describe the equipment used for tensile shear testing (e.g., universal testing machines).

- Interpreting Results: Explain how to interpret the results of tensile shear tests and use them to evaluate the strength of materials and joints.

Preventing Failure Due to Tensile Shear Force

- Material Selection: Choosing materials with appropriate tensile and shear strength for the application.

- Proper Design: Designing joints and components to minimize stress concentrations and distribute forces evenly.

- Manufacturing Processes: Using appropriate manufacturing processes to ensure joint integrity and prevent defects.

- Inspection and Maintenance: Regularly inspecting joints and components for signs of damage or wear, and performing maintenance as needed.

FAQs: Understanding Tensile Shear Force

Here are some frequently asked questions to clarify key aspects of tensile shear force and its applications.

What exactly is tensile shear force?

Tensile shear force is a combination of tension (pulling) and shear (sliding) forces acting on a material. Imagine trying to rip a piece of paper while also sliding the two halves past each other. That combined action is tensile shear. It’s a crucial consideration in many engineering designs.

How is tensile shear force different from pure tensile force?

Pure tensile force only involves pulling or stretching a material directly apart. Tensile shear force, on the other hand, involves a force component that tries to slide one part of the material relative to another. This sliding aspect differentiates it from pure tension.

Where is tensile shear force commonly found in real-world applications?

You’ll find tensile shear force in joints that are glued, bolted, or riveted. For example, in aircraft wings, the fasteners holding panels together experience tensile shear forces due to aerodynamic loads. These connections must be designed to withstand these stresses.

What factors affect a material’s resistance to tensile shear force?

A material’s shear strength, tensile strength, and the geometry of the connection all play a role. The type of adhesive used in a bonded joint also greatly influences how well it resists tensile shear force. Proper material selection and joint design are key.

So, there you have it – a deep dive into tensile shear force! Hopefully, this guide has shed some light on the subject. Now go forth and use this knowledge to build things that can withstand a little pull and tear!