Steel Crystalline Grain: The Secrets Revealed!

Understanding steel crystalline grain is fundamental to materials science, as these microstructural features significantly influence mechanical properties. Metallography, a crucial technique, provides detailed visualization of steel crystalline grain boundaries and their arrangement. Grain size, a key attribute of steel crystalline grain, directly impacts the yield strength and ductility of the material. The American Society for Testing and Materials (ASTM) establishes standardized methods for evaluating steel crystalline grain size and characteristics, ensuring consistency in materials testing and quality control. The interplay between these entities governs the overall performance and reliability of steel components.

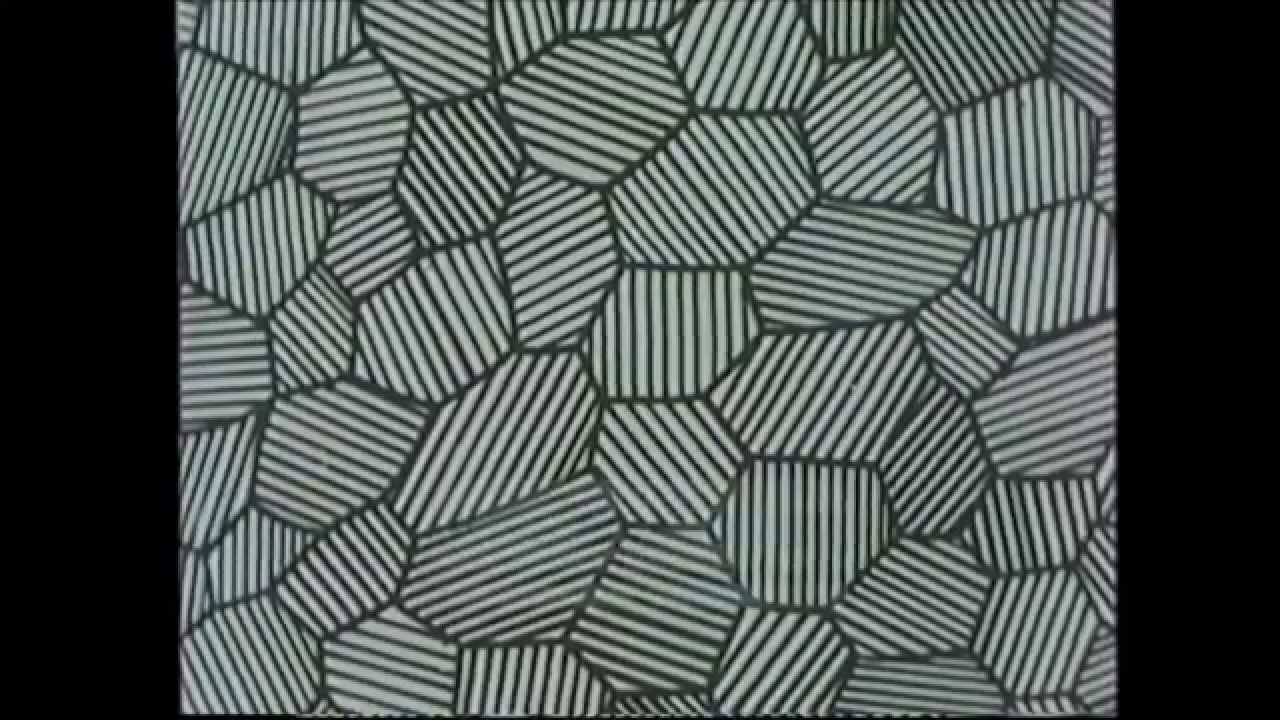

Image taken from the YouTube channel moodlemech , from the video titled Properties and Grain Structure .

Steel Crystalline Grain: Unveiling the Structure

Understanding the “steel crystalline grain” is fundamental to grasping the properties and behavior of steel. This article layout aims to provide a comprehensive explanation of these grains, their formation, characteristics, and impact.

Introduction to Crystalline Structure in Steel

The introduction should briefly explain that steel, like many other metals, is composed of a multitude of tiny crystals known as grains. It should highlight that the properties of steel are heavily influenced by the size, shape, and arrangement of these grains. The goal is to pique the reader’s interest in learning more about these fundamental building blocks.

- Emphasize the importance of "steel crystalline grain" in determining material properties.

- Briefly mention how grain structure is manipulated through processing.

Formation of Steel Crystalline Grains

This section delves into the process by which steel crystalline grains are formed. It should explain how the solidification of molten steel leads to the nucleation and growth of these grains.

Nucleation

Nucleation refers to the initial formation of stable, solid "steel crystalline grain" from the liquid phase. This section should cover:

- Homogeneous Nucleation: Explain this process where nuclei form spontaneously within the liquid.

- Heterogeneous Nucleation: This is where nuclei form on pre-existing surfaces, such as impurities or the walls of the mold. This is more common in practical steelmaking.

Grain Growth

After nucleation, the "steel crystalline grain" grow as more atoms from the liquid phase attach to their surfaces. This section will explain:

- The role of temperature gradients in influencing the direction of grain growth.

- How the rate of cooling affects the final grain size. Rapid cooling leads to smaller grains, while slow cooling leads to larger grains.

Characteristics of Steel Crystalline Grains

This section focuses on the measurable and observable attributes of "steel crystalline grain".

Grain Size

Grain size is a critical characteristic. It can be quantified using several methods.

- ASTM Grain Size Number (G): Explain how this number is determined through metallographic examination and comparison with standard charts. Relate larger G numbers to smaller grain sizes and vice versa.

- Average Grain Diameter: Explain how this is measured and calculated from microscopic images.

Grain Shape

While often simplified, grains aren’t perfectly spherical. This section should describe the different shapes that can be observed.

- Equiaxed Grains: Roughly spherical grains.

- Columnar Grains: Elongated grains formed during directional solidification.

Grain Boundaries

Grain boundaries are the interfaces between adjacent "steel crystalline grain". They play a significant role in the material’s properties.

- Explain that grain boundaries are regions of atomic disorder.

- Describe how grain boundaries can impede the movement of dislocations, thereby increasing strength and hardness.

- Mention the role of grain boundaries in corrosion and diffusion processes.

The Impact of Steel Crystalline Grain on Material Properties

This section is crucial for linking the microstructure of "steel crystalline grain" to the macroscopic properties of the steel.

Mechanical Properties

The grain size significantly affects the mechanical behavior of steel.

-

Strength and Hardness: Smaller grain sizes generally lead to higher strength and hardness, explained by the Hall-Petch relationship.

- Explain the Hall-Petch equation and its implications.

-

Ductility and Toughness: The relationship between grain size and ductility/toughness is more complex.

- Smaller grain size often improves toughness by providing more obstacles to crack propagation.

Corrosion Resistance

Grain boundaries are more susceptible to corrosion.

- Explain how the increased surface area of grain boundaries in fine-grained steel can affect corrosion rates.

- Mention strategies to mitigate grain boundary corrosion.

Magnetic Properties

Grain size and orientation also influence magnetic properties, especially in specialized steels.

- Briefly explain how grain alignment can affect magnetic permeability.

Manipulation of Steel Crystalline Grain

This section will discuss techniques used to control the "steel crystalline grain" structure.

Heat Treatment

Heat treatment is a powerful method for altering grain size and microstructure.

- Annealing: Describe how annealing at high temperatures promotes grain growth.

- Normalizing: Explain how normalizing refines grain size compared to annealing.

- Quenching and Tempering: Describe how quenching produces a martensitic structure, which can then be tempered to achieve desired properties and grain size.

Alloying

Adding alloying elements can also influence grain growth.

- Explain how certain alloying elements can act as grain refiners.

Thermomechanical Processing

Combining heat treatment and mechanical deformation can result in very fine-grained steels.

- Briefly describe techniques like controlled rolling and forging.

Observation and Analysis of Steel Crystalline Grain

This section details the techniques used to observe and analyze the "steel crystalline grain" structure.

Metallography

Metallography involves preparing and examining polished and etched steel samples under a microscope.

- Sample Preparation: Briefly describe the steps involved in preparing a metallographic sample (cutting, mounting, grinding, polishing, etching).

- Microscopy: Explain the use of optical and electron microscopy to visualize the "steel crystalline grain" structure.

Quantitative Analysis

Image analysis techniques are used to quantify grain size and other microstructural features.

- Explain the use of image analysis software to measure grain size distribution.

The layout above aims to provide a logical and structured flow of information, ensuring clarity and comprehension for readers interested in learning about "steel crystalline grain".

Steel Crystalline Grain FAQs: Understanding the Structure

Here are some frequently asked questions to help you better understand the crystalline structure of steel.

What exactly is a steel crystalline grain?

A steel crystalline grain, also known as a grain or crystallite, is a small, individual crystal within a polycrystalline steel material. Each grain has a specific crystallographic orientation. These grains are the building blocks that give steel its properties.

How do the size and shape of steel crystalline grain affect its properties?

The size and shape of steel crystalline grain have a significant impact on its mechanical properties. Generally, smaller grains lead to higher strength and toughness because they impede the movement of dislocations, which are defects in the crystal structure.

How are steel crystalline grains formed during the manufacturing process?

Steel crystalline grains form during the solidification process as molten steel cools. The rate of cooling, the presence of alloying elements, and subsequent heat treatments all influence the size and shape of the resulting steel crystalline grain structure.

Can the size of steel crystalline grain be changed after manufacturing?

Yes, the size of steel crystalline grains can be altered through heat treatments like annealing or normalizing. These processes involve heating the steel to a specific temperature and then cooling it at a controlled rate, allowing the grain structure to be modified to achieve desired properties.

So, there you have it! Hopefully, you’ve unlocked some of the secrets hidden within steel crystalline grain. Now go forth and put that knowledge to good use. Happy tinkering!