Sheet Metal Ducts Aircon: Ceiling Plans That Save You Money

Optimizing sheet metal ducts aircon in ceiling plans requires a multifaceted approach, considering factors like airflow efficiency, material selection, and installation costs. Effective planning leverages software tools such as AutoCAD for precise layouts, enabling architects and HVAC engineers to collaborate effectively. Furthermore, organizations like ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning Engineers) provide essential standards and guidelines for ductwork design. These standards significantly influence energy consumption and long-term savings for building owners.

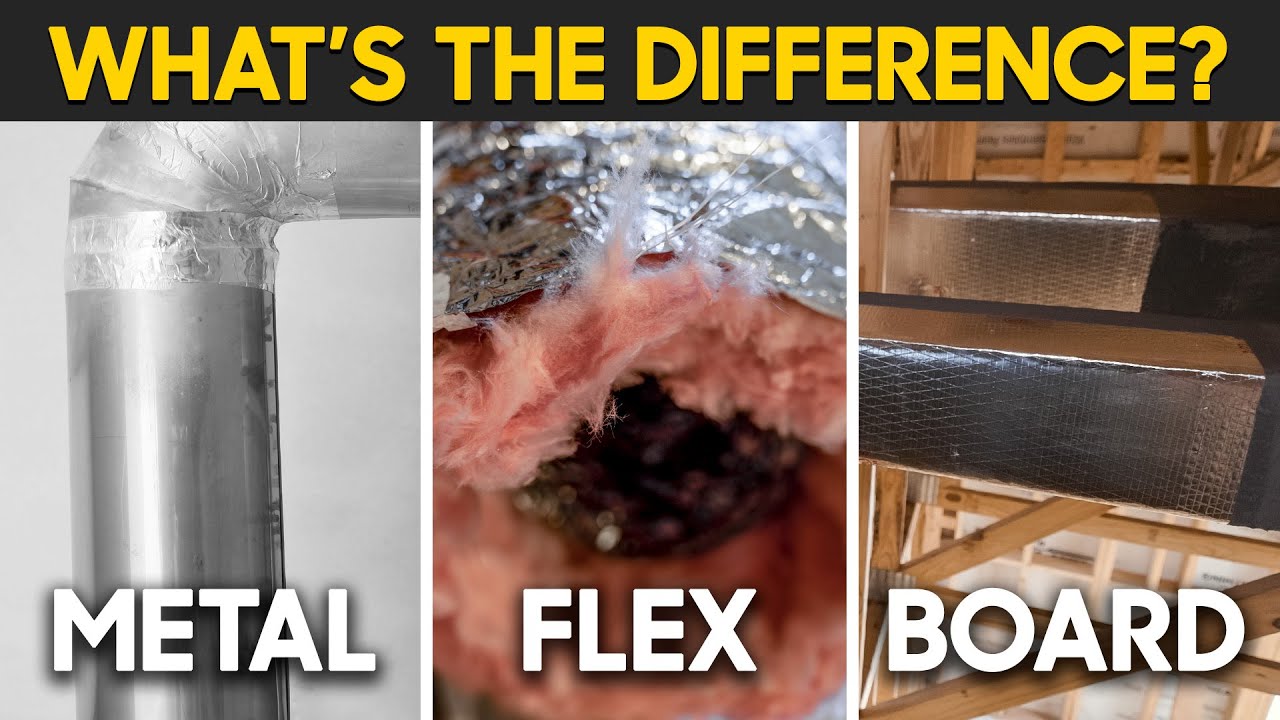

Image taken from the YouTube channel Matt Risinger , from the video titled Flex vs. Metal vs. Duct Board: Differences and Use Cases .

Structuring an Article on Sheet Metal Ducts Aircon in Ceiling Plans for Cost Savings

This outline details the best structure for an informative article focusing on how the strategic use of sheet metal ducts aircon in ceiling plans can result in significant cost savings. The article will aim to be accessible to a broad audience, including homeowners, building managers, and contractors involved in HVAC system design and installation.

Introduction: Setting the Stage for Savings

The introductory paragraph should immediately grab the reader’s attention and establish the core value proposition: reducing costs through optimized ductwork design.

- Hook: Start with a compelling statistic or a relatable anecdote about high energy bills.

- Problem Statement: Briefly highlight the common issues of poorly designed air conditioning ductwork – inefficiency, wasted energy, and increased costs.

- Solution Introduction: Introduce sheet metal ducts as a durable and efficient option, and emphasize the importance of proper ceiling plan design for maximizing their benefits.

- Thesis Statement: Clearly state the article’s purpose: to explain how strategic planning of sheet metal ductwork in ceiling plans can lead to substantial cost savings.

Understanding Sheet Metal Ducts: Advantages and Considerations

This section provides a foundation for understanding the benefits and limitations of sheet metal ducts in air conditioning systems.

Material Properties and Advantages

- Durability and Longevity: Explain the inherent strength and resistance to wear and tear of sheet metal.

- Airflow Efficiency: Discuss the smooth interior surfaces of sheet metal ducts and their impact on reducing friction and improving airflow.

- Fire Resistance: Highlight the non-combustible nature of sheet metal and its contribution to building safety.

- Material Options: Briefly mention different types of sheet metal (e.g., galvanized steel, aluminum) and their specific properties.

Design Considerations for Sheet Metal Ducts

- Sizing: Emphasize the crucial role of accurate duct sizing based on airflow requirements. Explain how undersized ducts lead to increased static pressure and reduced efficiency.

- Sealing: Discuss the importance of properly sealing duct joints to prevent air leaks and energy loss. Different sealing methods can be mentioned (e.g., mastic, foil tape).

- Insulation: Explain the necessity of insulating sheet metal ducts, especially in unconditioned spaces, to minimize heat gain or loss. Different insulation materials and their R-values should be discussed.

- Acoustics: Address potential noise issues associated with sheet metal ducts and strategies for noise reduction (e.g., duct lining, sound attenuators).

Optimizing Ceiling Plans for Cost Savings

This section is the core of the article, detailing how ceiling plan design directly impacts the cost-effectiveness of sheet metal ductwork.

Minimizing Duct Length and Complexity

- Direct Routing: Advocate for the most direct routes possible for duct runs to reduce material usage and friction loss. Use examples and diagrams to illustrate effective and ineffective routing.

- Strategic Placement of Air Handling Units (AHUs): Explain how the location of the AHU can significantly impact ductwork length and complexity.

- Avoiding Obstructions: Discuss the importance of coordinating with other building systems (e.g., plumbing, electrical) to avoid unnecessary detours and bends in the ductwork.

Reducing Static Pressure and Improving Airflow

- Proper Duct Sizing: Reinforce the importance of correct duct sizing based on airflow calculations. Include a simple example of how incorrect sizing affects static pressure.

- Minimizing Bends and Fittings: Explain how each bend and fitting introduces resistance to airflow. Recommend using smooth, gradual bends whenever possible.

- Using Efficient Fittings: Discuss different types of fittings (e.g., elbows, tees, reducers) and their impact on airflow. Highlight fittings with lower pressure drop.

Energy Efficiency and Insulation Strategies

- Strategic Duct Placement in Conditioned Spaces: Emphasize the benefit of locating ducts within the conditioned space to minimize heat gain or loss.

- Optimized Insulation Thickness: Explain how to determine the appropriate insulation thickness based on climate zone and building codes.

- Proper Insulation Installation: Stress the importance of correct insulation installation to avoid gaps and air leakage.

Table: Common Ceiling Plan Design Issues and Their Cost Impact

| Issue | Cause | Cost Impact | Solution |

|---|---|---|---|

| Undersized Ducts | Incorrect airflow calculations | Increased energy consumption, reduced system lifespan | Recalculate airflow requirements, replace ducts with appropriately sized ones |

| Excessive Duct Length | Poor planning, routing around obstacles | Increased material costs, higher static pressure, energy waste | Optimize duct routing, relocate AHU if possible, coordinate with other systems |

| Leaky Duct Joints | Improper sealing | Significant energy loss, increased utility bills | Properly seal all duct joints with mastic or foil tape |

| Insufficient Insulation | Inadequate insulation thickness | Heat gain/loss, reduced system efficiency, condensation risks | Increase insulation thickness, ensure proper installation |

| Excessive Bends | Poor routing, obstructions | Increased static pressure, reduced airflow, higher energy consumption | Minimize bends, use gradual bends, relocate obstacles if possible |

Tools and Technologies for Efficient Ceiling Plan Design

This section explores tools and technologies that can aid in designing optimized ceiling plans for sheet metal ductwork.

- CAD Software (Computer-Aided Design): Explain how CAD software allows for precise ductwork layout and interference checking.

- BIM (Building Information Modeling): Discuss the benefits of using BIM to create a comprehensive 3D model of the building, facilitating coordination between different building systems.

- Duct Sizing Calculators: Highlight the availability of online duct sizing calculators and their role in ensuring proper duct dimensions.

- Airflow Simulation Software: Mention the use of computational fluid dynamics (CFD) software to simulate airflow patterns and identify potential problems.

Case Studies: Real-World Examples of Cost Savings

This section presents real-world examples of how optimizing sheet metal ductwork in ceiling plans has led to significant cost savings.

- Commercial Building: Describe a case study where optimizing duct routing and insulation resulted in a substantial reduction in energy consumption. Quantify the cost savings achieved.

- Residential Home: Present a case study where proper duct sizing and sealing improved the comfort and energy efficiency of a home. Again, quantify the cost savings.

- Industrial Facility: Showcase a case study where using efficient fittings and minimizing duct length reduced static pressure and improved the performance of an industrial HVAC system.

These case studies should include specific details, such as:

- Building type and size

- HVAC system specifications

- Ductwork modifications implemented

- Quantifiable cost savings achieved (e.g., percentage reduction in energy bills)

By following this structure, the article will provide a comprehensive and informative guide on how to save money by strategically planning sheet metal ducts in aircon ceiling plans.

So, there you have it! Hopefully, this gives you a better handle on how smart sheet metal ducts aircon in ceiling plans can really impact your bottom line. Now go forth and optimize!