Sauter Mean Diameter: The Ultimate Guide You Need To Know

The spray nozzle design significantly influences the sauter mean diameter (SMD), a crucial parameter in droplet characterization. Computational Fluid Dynamics (CFD) simulations provide a robust method for predicting SMD, enabling engineers to optimize designs. Specifically, understanding the role of surface tension directly impacts the accuracy of SMD calculations, vital for applications ranging from fuel injection to spray drying. Therefore, precise control over the sauter mean diameter enables industries to refine processes for better efficiency and performance. Organizations like ASTM International provide standardized methods to measure and define SMD, ensuring consistent comparisons and applications.

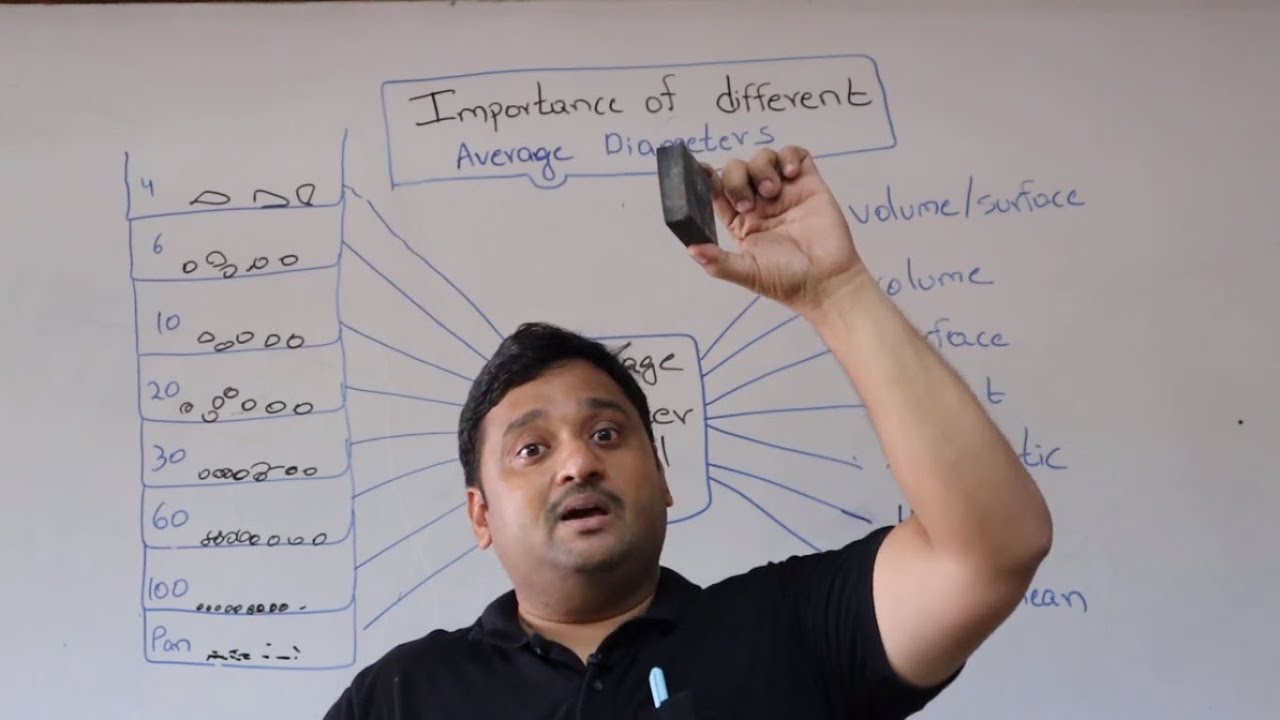

Image taken from the YouTube channel Dr. Surendra Sasikumar Jampa (PhD,Chem Engg, IITB) , from the video titled Lec 7: Why Different Average Diameters Exist?(Sautermean, Volumemean etc):Mechanical Unit Operations .

Understanding Sauter Mean Diameter: A Comprehensive Guide

This article will delve into the concept of Sauter Mean Diameter (SMD), explaining its significance and applications. We’ll cover its definition, calculation methods, factors influencing it, and its practical importance. The focus throughout will be on providing a clear and concise understanding of the "sauter mean diameter" for a diverse audience.

1. Defining Sauter Mean Diameter

This section will establish a solid foundation by defining what Sauter Mean Diameter actually represents.

1.1. What is Sauter Mean Diameter?

The Sauter Mean Diameter (often abbreviated as D32) is a way to represent the average particle size within a collection of particles. It’s specifically defined as the diameter of a sphere that has the same surface area to volume ratio as the entire spray or particulate system.

- Surface Area to Volume Ratio: Explain the importance of this ratio. High surface area to volume ratios are generally desirable in processes like combustion or chemical reactions as they provide more area for interaction.

- Why Use SMD? Briefly explain why SMD is a better measure than just average particle size. Emphasize its relation to performance.

1.2. The Mathematical Representation

This subsection will provide the formula for calculating SMD.

SMD = ∑(ni di^3) / ∑(ni di^2)

Where:

- ni = Number of particles with diameter di

- di = Diameter of a single particle

Table: Key to SMD Formula Variables

| Variable | Description | Unit |

|---|---|---|

| ni | Number of particles of diameter ‘di’ | count |

| di | Diameter of a single particle | µm/mm |

1.3. Differences Between SMD and Other Mean Diameters

It’s crucial to differentiate SMD from other common particle size metrics.

- Arithmetic Mean Diameter: Simply the average particle size. Less sensitive to finer particles.

- Volume Mean Diameter: Represents the diameter of a sphere having the same volume as the average particle.

- Why SMD is Preferred for Spray Characterization: Emphasize that SMD is particularly useful for characterizing sprays because it directly relates to the surface area available for evaporation or reaction.

2. Methods for Determining Sauter Mean Diameter

This section will detail the methods used to measure SMD.

2.1. Direct Measurement Techniques

These methods involve directly measuring the size of particles.

- Microscopy: Optical or electron microscopy, followed by image analysis to measure individual particle sizes. It can be labor-intensive but provides detailed information.

- Laser Diffraction: This is a common technique where particles diffract a laser beam. The diffraction pattern is then analyzed to determine particle size distribution and, subsequently, SMD.

2.2. Indirect Measurement Techniques

These methods infer SMD from other measurable parameters.

- Phase Doppler Anemometry (PDA): Measures both the size and velocity of individual droplets in a spray.

- Light Scattering Techniques: Analyze the scattering of light by particles to determine their size and concentration.

2.3. Factors Affecting Measurement Accuracy

Regardless of the method chosen, several factors can influence the accuracy of SMD measurements.

- Sampling Bias: Ensuring a representative sample is crucial.

- Instrument Calibration: Regular calibration is necessary to maintain accuracy.

- Particle Shape: The assumption of spherical particles can introduce errors if the particles are irregular in shape.

- Data Processing: Accurate data processing and analysis are critical for reliable results.

3. Factors Influencing Sauter Mean Diameter

This section will explore the variables that can impact the final Sauter Mean Diameter.

3.1. Material Properties

The properties of the liquid being atomized (in spray applications) significantly affect SMD.

- Viscosity: Higher viscosity generally leads to larger droplets (higher SMD).

- Surface Tension: Higher surface tension also tends to increase SMD, as it requires more energy to break the liquid into smaller droplets.

- Density: Density can influence the atomization process and, consequently, SMD.

3.2. Atomization Conditions

The method and conditions under which a liquid is atomized play a crucial role.

- Nozzle Type: Different nozzle designs produce different droplet size distributions and SMDs. (e.g., pressure-swirl, air-blast, ultrasonic)

- Pressure: Higher injection pressure in spray nozzles usually results in smaller droplets (lower SMD).

- Flow Rate: The flow rate of the liquid can impact droplet size, especially in pressure-driven systems.

- Temperature: Temperature can affect the liquid’s viscosity and surface tension, indirectly influencing SMD.

3.3. Environmental Factors

The surrounding environment can also impact the final Sauter Mean Diameter.

- Ambient Pressure: Higher ambient pressure can influence droplet breakup and evaporation.

- Ambient Temperature: The temperature of the surrounding gas affects the evaporation rate of the droplets.

- Gas Velocity: The velocity of the surrounding gas can aid or hinder atomization, depending on the nozzle design.

4. Applications of Sauter Mean Diameter

This section will highlight the practical applications where SMD is important.

4.1. Combustion Engineering

SMD is a critical parameter in combustion processes.

- Fuel Injection: In internal combustion engines, SMD affects fuel evaporation, air-fuel mixing, and combustion efficiency.

- Spray Drying: In spray drying, SMD affects the size and uniformity of the dried particles.

- Burner Design: Burner designs are often optimized to achieve a specific SMD for efficient combustion.

4.2. Agriculture

SMD is crucial for pesticide and fertilizer application.

- Pesticide Application: Optimal SMD ensures effective coverage of plants with minimal drift.

- Fertilizer Application: SMD influences the uptake of fertilizers by plants.

4.3. Pharmaceutical Industry

SMD is important in drug delivery systems.

- Inhalers: Particle size is critical for effective drug delivery to the lungs.

- Powder Coating: SMD affects the uniformity and finish of powder coatings.

4.4. Other Applications

- Inkjet Printing: SMD controls the size and placement of ink droplets.

- Cosmetics: SMD affects the texture and application of cosmetic products.

By breaking down the concept of Sauter Mean Diameter into these well-defined sections, this guide provides a clear and informative explanation suitable for a wide audience. The progressive nesting of headings and the use of various formatting elements like tables and bullet points enhance readability and understanding.

Sauter Mean Diameter: Frequently Asked Questions

These FAQs address common questions about the Sauter Mean Diameter (SMD) and its applications.

What exactly does Sauter Mean Diameter (SMD) represent?

Sauter Mean Diameter, often abbreviated as SMD or D32, represents the diameter of a sphere that has the same volume-to-surface area ratio as a collection of droplets or particles. It’s a crucial parameter for characterizing dispersed systems.

Why is Sauter Mean Diameter important?

SMD is critical because it directly influences processes dependent on surface area, such as evaporation, combustion, and chemical reactions. A smaller sauter mean diameter means a larger surface area per unit volume, leading to faster reaction rates.

How is Sauter Mean Diameter typically measured?

Several techniques can determine the sauter mean diameter, including laser diffraction, phase Doppler anemometry (PDA), and image analysis. The choice of method depends on the size range and characteristics of the particles or droplets being measured.

Where is Sauter Mean Diameter commonly used?

SMD is widely used in various industries, including spray nozzle design, fuel injection analysis, powder coating applications, and pharmaceutical aerosol development. It allows engineers and scientists to optimize these processes for efficiency and effectiveness.

And there you have it! Hope this guide helped shed some light on the often-misunderstood sauter mean diameter. Now go forth and optimize those sprays!