Rayleigh Jet Breakup: How It Works & Why It Matters!

Surface tension, a key property influencing fluid dynamics, directly affects the rayleigh mode jet breakup how it works. Lord Rayleigh’s work established the theoretical foundation for understanding this phenomenon. Applications are broad, ranging from inkjet printing, where controlled droplet formation is crucial, to industrial spray nozzles, where optimizing droplet size impacts efficiency. Computational fluid dynamics, or CFD, models often simulate rayleigh mode jet breakup how it works to predict and optimize these processes, providing valuable insights into the underlying physics.

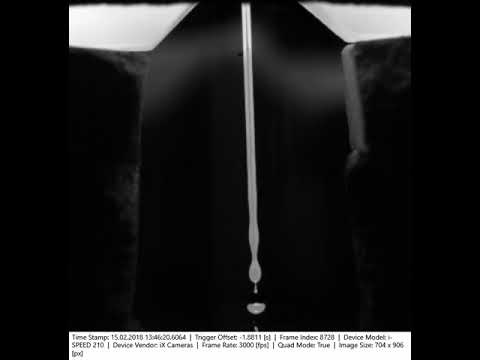

Image taken from the YouTube channel Nils Ellendt , from the video titled Rayleigh jet breakup of liquid 316L .

Rayleigh Jet Breakup: Deconstructing the Phenomenon

This article aims to provide a comprehensive understanding of Rayleigh jet breakup, focusing on the mechanism behind it and its practical implications. The core focus will be explaining the Rayleigh mode instability and its role in fluid stream disintegration.

Understanding Fluid Jets

Before diving into the specifics of Rayleigh breakup, it’s important to understand what constitutes a fluid jet and the forces acting upon it.

Defining a Fluid Jet

A fluid jet is essentially a stream of liquid (or gas, though we’ll primarily focus on liquids here) exiting an orifice under pressure. These jets can be observed in various scenarios, from a garden hose to inkjet printers.

Surface Tension: A Key Player

The surface tension of a liquid plays a crucial role in its behavior. It’s a property caused by the cohesive forces between liquid molecules. Surface tension creates an inward force that minimizes the surface area of the liquid, causing droplets to form. Think of water beading on a waxed surface.

- Surface tension aims to minimize surface area.

- It creates a "skin" on the liquid’s surface.

- It’s measured in units of force per unit length (e.g., N/m).

Viscosity: Another Important Factor

Viscosity is the resistance of a fluid to flow. High viscosity fluids (like honey) resist flow more than low viscosity fluids (like water). Viscosity influences the jet’s stability and how quickly it breaks up.

Rayleigh Instability: The Mechanism of Breakup

Lord Rayleigh mathematically described the instability responsible for the breakup of liquid jets in the late 19th century. This phenomenon is known as Rayleigh instability or Rayleigh–Plateau instability.

The Origin of Disturbances

Even a seemingly uniform liquid jet is subject to minor disturbances. These disturbances can be thought of as slight variations in the jet’s diameter along its length.

Amplification of Disturbances

Rayleigh discovered that certain wavelengths of these disturbances are amplified due to the interplay between surface tension and the jet’s geometry.

- Surface Tension’s Role: Surface tension tries to minimize the liquid’s surface area.

- Wavelength Selection: Wavelengths longer than the circumference of the jet (λ > 2πr, where r is the jet’s radius) are unstable and tend to grow.

Minimizing Surface Area

The driving force is the tendency of the liquid to minimize its surface area. By forming droplets, the total surface area of the liquid is reduced compared to a continuous cylindrical jet.

From Instability to Breakup

As these unstable disturbances grow, the jet begins to neck down at certain points and bulge out at others. This process continues until the jet separates into individual droplets.

Parameters Influencing Rayleigh Breakup

Several parameters affect the speed and characteristics of the Rayleigh breakup process.

Liquid Properties

- Surface Tension: Higher surface tension generally promotes faster breakup and smaller droplets.

- Viscosity: Higher viscosity can dampen the instability, delaying the breakup and leading to longer droplets.

- Density: Density influences the jet’s inertia and can affect the breakup wavelength.

Jet Parameters

- Jet Diameter: A smaller jet diameter tends to result in smaller droplets. The most unstable wavelength is proportional to the jet’s radius.

- Jet Velocity: Higher jet velocity can introduce aerodynamic forces that complicate the breakup process, potentially leading to atomization (smaller droplets) rather than purely Rayleigh-driven breakup.

External Factors

- Ambient Pressure: Pressure can influence the liquid’s boiling point and evaporation rate, potentially affecting breakup.

- Airflow: Airflow can introduce additional disturbances and shear forces, leading to different breakup patterns.

Practical Implications and Applications

Rayleigh jet breakup is not merely a theoretical concept; it has numerous applications and implications across various fields.

Inkjet Printing

Inkjet printers rely on the controlled breakup of liquid ink jets to precisely deposit ink onto paper. Understanding and controlling Rayleigh instability is crucial for achieving high-resolution printing.

Spray Coating

In spray coating applications, the goal is often to produce a fine mist of droplets. Rayleigh breakup plays a role in the initial stages of droplet formation, although other atomization mechanisms may become dominant.

Fuel Injection

In internal combustion engines, fuel injectors atomize liquid fuel into a fine spray. Understanding the factors influencing jet breakup is essential for efficient combustion and reduced emissions.

Microfluidics

In microfluidic devices, precise control over droplet formation is often required. Rayleigh instability can be harnessed to generate monodisperse (uniform size) droplets for various applications.

Industrial Processes

Many industrial processes, such as fiber spinning and liquid-liquid extraction, involve the formation and breakup of liquid jets. A fundamental understanding of Rayleigh instability is vital for optimizing these processes.

| Application | Importance of Rayleigh Breakup |

|---|---|

| Inkjet Printing | Critical for droplet generation |

| Spray Coating | Initial droplet formation |

| Fuel Injection | Fuel atomization |

| Microfluidics | Controlled droplet generation |

| Industrial Processes | Process optimization |

Frequently Asked Questions: Rayleigh Jet Breakup

Here are some common questions about Rayleigh jet breakup and its significance, addressed simply and directly.

What exactly is Rayleigh jet breakup?

Rayleigh jet breakup is the process where a liquid jet, due to surface tension forces overcoming inertia, spontaneously breaks into droplets. This instability arises from the tendency to minimize surface area, leading to a varicose deformation (a bulge-like swelling and thinning) that eventually pinches off. This instability of jets is referred as rayleigh mode jet breakup how it works because it was first described by Lord Rayleigh.

Why does surface tension cause a liquid jet to break up?

Surface tension acts to minimize the surface area of the liquid. A sphere has the smallest surface area for a given volume. When a jet is disturbed, even slightly, surface tension amplifies these disturbances, leading to the formation of necks and bulges. Eventually, the necks thin out to zero thickness and the jet breaks into droplets.

How does viscosity affect Rayleigh jet breakup?

Viscosity resists the flow of the liquid and damps the growth of the instabilities. Higher viscosity generally slows down the rate of Rayleigh jet breakup how it works, potentially even suppressing it altogether if the viscosity is high enough. A very viscous fluid can still break up, but it’s likely to form longer threads before finally separating into droplets.

Why is understanding Rayleigh jet breakup important?

Understanding Rayleigh jet breakup is crucial in various applications, including ink-jet printing, spray cooling, and even understanding the formation of raindrops. Controlling and predicting this phenomenon allows us to optimize the size and distribution of droplets produced in these processes. By understanding rayleigh mode jet breakup how it works, processes can be controlled effectively.

So, next time you see a perfectly formed droplet, remember rayleigh mode jet breakup how it works! Hopefully, this helped make a complicated topic a bit more approachable. Now go forth and impress your friends with your fluid dynamics knowledge!