Unlock the Secrets: Principle Stresses Rectangle!

Understanding stress distribution is critical in structural engineering, and the principle stresses rectangle provides a powerful tool for this purpose. Mohr’s Circle, a graphical representation technique, helps visualize the transformation of stresses, directly informing the construction of the principle stresses rectangle. The American Society of Civil Engineers (ASCE) emphasizes the importance of accurately determining these stresses in ensuring the safety and stability of infrastructure projects. Effective utilization of principle stresses rectangle contributes to safer designs developed by Structural Analysis Software, enhancing the integrity of built environments worldwide.

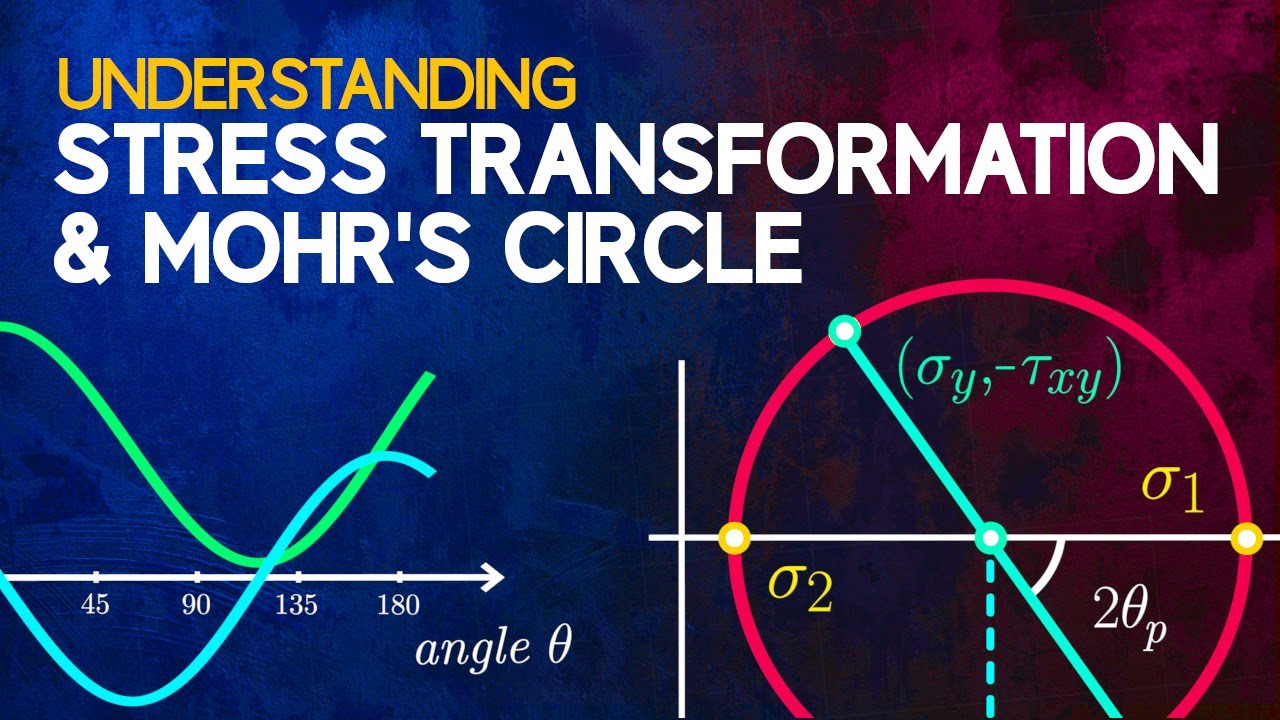

Image taken from the YouTube channel The Efficient Engineer , from the video titled Understanding Stress Transformation and Mohr’s Circle .

Unlocking the Secrets: Principle Stresses in a Rectangle

Understanding the concept of principle stresses within a rectangular element is crucial in various engineering disciplines. This article provides a comprehensive breakdown of the ‘principle stresses rectangle’ topic, focusing on what they are, how to determine them, and their practical significance.

Defining Principle Stresses and Their Significance

Principle stresses represent the maximum and minimum normal stresses acting on a material at a specific point. Crucially, these stresses act on planes where the shear stress is zero. In the context of a ‘principle stresses rectangle’, this means we are analyzing the stresses within a small, rectangular element of a larger structure.

- Normal Stress: Stress acting perpendicular to a surface. Tension is positive, and compression is negative.

- Shear Stress: Stress acting parallel to a surface.

Why are these principle stresses important? Because they:

- Help predict material failure: Materials typically fail due to exceeding their tensile or compressive strength, directly related to principle stresses.

- Provide a simplified stress state: By understanding the maximum and minimum normal stresses, we can more easily analyze the overall stress condition at a point.

- Inform design decisions: Knowing the magnitude and direction of principle stresses allows engineers to optimize designs to withstand applied loads.

Determining Principle Stresses within a Rectangle

To find the principle stresses within a rectangle, we generally start with a known state of stress represented by normal stresses in the x and y directions (σx and σy, respectively) and shear stress (τxy). We then use these values to calculate the principle stresses (σ1 and σ2).

Equations for Principle Stresses

The equations for determining principle stresses are:

- Maximum Principle Stress (σ1): σ1 = (σx + σy)/2 + √[((σx – σy)/2)^2 + τxy^2]

- Minimum Principle Stress (σ2): σ2 = (σx + σy)/2 – √[((σx – σy)/2)^2 + τxy^2]

Determining the Orientation of Principle Planes

Not only do we need to know the magnitude of the principle stresses, but also the direction they act upon. This direction is defined by the angle θp, measured from the x-axis.

- Equation for the Angle of Principle Planes (θp): θp = 0.5 * arctan(2τxy / (σx – σy))

This equation provides two possible values for θp, 90 degrees apart. These angles represent the orientation of the planes where the maximum and minimum principle stresses act. To determine which angle corresponds to which principle stress, you can use the stress transformation equations.

Stress Transformation Equations

These equations relate the stresses on an element oriented at an angle θ to the known stresses σx, σy, and τxy:

- Normal Stress at Angle θ (σθ): σθ = (σx + σy)/2 + ((σx – σy)/2) cos(2θ) + τxy sin(2θ)

- Shear Stress at Angle θ (τθ): τθ = -((σx – σy)/2) sin(2θ) + τxy cos(2θ)

Using the calculated θp, you can substitute into these equations to find the normal and shear stresses acting on those rotated planes. Because the shear stress should be zero on the principle planes, the value of σθ will directly correspond to either σ1 or σ2.

Visualizing Principle Stresses

Imagine our ‘principle stresses rectangle’ as a tiny square within a larger structure. The calculated principle stresses, σ1 and σ2, represent the maximum and minimum normal stresses acting on this square after it’s been rotated by the angle θp. This rotation aligns the element with the principle planes, where shear stresses are zero. The result is a new rectangle, oriented differently, with only normal stresses acting on its sides.

Mohr’s Circle Representation

Mohr’s Circle is a graphical representation of the stress state at a point. It allows us to visualize the transformation of stresses as the element is rotated. For the ‘principle stresses rectangle’, the circle’s center lies at ((σx + σy)/2, 0), and its radius is √[((σx – σy)/2)^2 + τxy^2]. The points where the circle intersects the horizontal axis represent the principle stresses, σ1 and σ2.

Practical Application

Consider a rectangular beam subjected to bending. Different points within the beam will experience different stress states. By calculating the principle stresses at these points, engineers can:

- Identify areas of maximum tensile stress, where cracks are most likely to initiate.

- Determine the necessary material strength to prevent failure.

- Optimize the beam’s shape to distribute stress more evenly.

A table summarizing a practical example calculation can also provide substantial clarity:

| Parameter | Value |

|---|---|

| σx (Normal Stress in X direction) | 100 MPa |

| σy (Normal Stress in Y direction) | 20 MPa |

| τxy (Shear Stress) | 50 MPa |

| Calculated Values: | |

| σ1 (Maximum Principle Stress) | 130.9 MPa |

| σ2 (Minimum Principle Stress) | -10.9 MPa |

| θp (Angle of Principle Plane) | 26.6 degrees |

FAQs About Principle Stresses in a Rectangle

Here are some frequently asked questions to help you better understand principle stresses in a rectangle and how they relate to structural analysis.

What are principle stresses and why are they important?

Principle stresses are the maximum and minimum normal stresses at a point on a structural element, like a rectangle. They are important because they indicate the directions where shear stresses are zero, revealing the locations where the material is most susceptible to failure under tension or compression.

How are principle stresses determined in a rectangular element?

Principle stresses are determined through stress transformation equations that take into account the normal and shear stresses acting on the element. These equations allow us to find the angle of orientation where the normal stress is maximized (principle stress) and shear stress is zero. In the case of a principle stresses rectangle, the equations use the normal stresses and shear stress acting on the rectangle.

What is the significance of the angle of principle stresses?

The angle of principle stresses indicates the orientation of the plane where the principle stresses act. This angle is crucial for aligning reinforcement in concrete structures or for understanding crack propagation in materials subjected to stress. For a principle stresses rectangle, knowing this angle helps in predicting how it will deform and potentially fail.

Can a rectangular element experience only principle stresses?

No. While principle stresses exist at every point within a stressed body, including a rectangular element, there are also shear stresses present on other planes. The planes where principle stresses act are specifically defined by the absence of shear stress. The presence of principle stresses within a rectangle is critical for understanding its structural integrity.

Alright, so you’ve got a handle on the principle stresses rectangle now. Go on and put that knowledge to good use and remember what you learned. Happy designing!