Polycarbonate vs. Solvents: Shocking Resistance Truth!

Polycarbonate, a durable thermoplastic polymer, finds extensive application in various industries, including the manufacturing of safety glasses where its impact resistance is crucial. The chemical compatibility of polycarbonate is a significant consideration, particularly concerning its interaction with solvents, as highlighted in research conducted by Bayer MaterialScience. The solubility parameter, a key metric used by organizations such as ASTM International, helps predict whether a given solvent will dissolve a particular polymer. Consequently, the central question of is polycarbonate plastic resistant to polar aprotic solvents demands careful examination to understand its limitations in specific chemical environments.

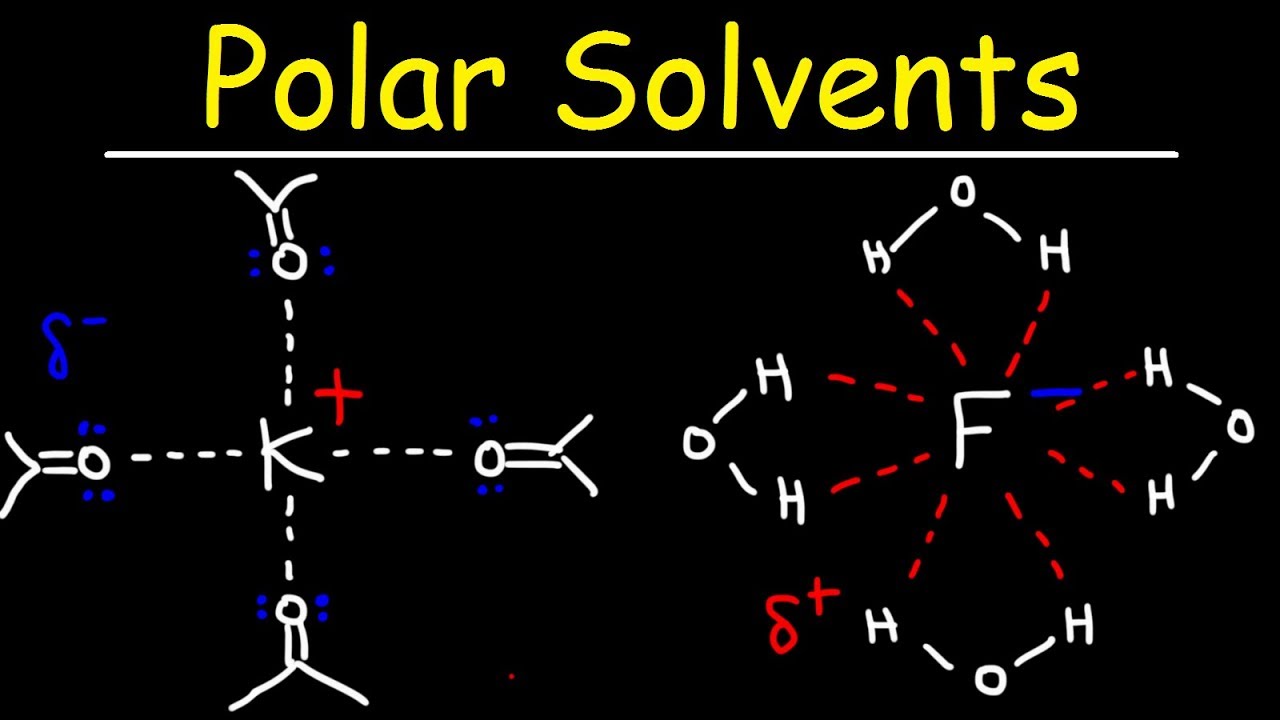

Image taken from the YouTube channel The Organic Chemistry Tutor , from the video titled Polar Protic Solvents and Polar Aprotic Solvents For SN1 & SN2 Reactions .

Polycarbonate vs. Solvents: Unveiling the Resistance Truth!

Let’s explore the chemical resistance of polycarbonate plastic, specifically addressing the question: is polycarbonate plastic resistant to polar aprotic solvents?

Understanding Polycarbonate

Polycarbonate (PC) is a strong, transparent thermoplastic known for its impact resistance and optical clarity. It’s commonly used in applications ranging from safety glasses and automotive components to electronic housings and roofing panels. However, its resistance to various chemicals, including solvents, varies significantly depending on the specific chemical and the conditions of exposure.

The Challenge: Polar Aprotic Solvents

Polar aprotic solvents are a class of solvents characterized by their high polarity but lack of hydrogen atoms bonded to oxygen or nitrogen (i.e., they can’t donate protons). Common examples include:

- Dimethylformamide (DMF)

- Dimethyl sulfoxide (DMSO)

- Acetone

- Acetonitrile

- N-Methylpyrrolidone (NMP)

These solvents often exhibit strong solvency power, making them useful in various industrial and laboratory processes. However, this solvency power can also pose a threat to certain plastics, including polycarbonate.

Polycarbonate’s Vulnerability

The answer to whether polycarbonate is resistant to polar aprotic solvents is generally no, not resistant. While some resistance might exist at low concentrations or short exposure times, prolonged or repeated exposure to these solvents can lead to significant degradation. The mechanism of degradation usually involves:

- Solvent penetration: The solvent molecules permeate the polycarbonate structure.

- Chain scission: The solvent weakens the bonds between the polymer chains, leading to cracking and embrittlement.

- Swelling and softening: The polycarbonate may swell as it absorbs the solvent, leading to dimensional changes and a reduction in its mechanical properties.

- Dissolution (in extreme cases): In some instances, particularly with aggressive solvents or high concentrations, the polycarbonate can partially or completely dissolve.

Factors Influencing Resistance

The degree of polycarbonate’s resistance to polar aprotic solvents is influenced by several factors:

- Specific Solvent: The type of solvent is crucial. For example, acetone may have a less aggressive effect than DMF or NMP.

- Concentration: Higher concentrations of the solvent will typically lead to more rapid degradation.

- Exposure Time: Longer exposure durations allow for greater solvent penetration and increased degradation.

- Temperature: Elevated temperatures accelerate the rate of chemical reactions, leading to faster degradation.

- Stress: Applied stress on the polycarbonate part can exacerbate solvent-induced cracking (environmental stress cracking).

- Polycarbonate Grade: Different grades of polycarbonate may have varying levels of chemical resistance due to additives or modifications in the polymer structure.

Practical Considerations and Mitigation Strategies

Given the vulnerability of polycarbonate to polar aprotic solvents, several strategies can be employed to minimize or avoid degradation:

-

Material Selection: If exposure to polar aprotic solvents is unavoidable, consider alternative plastics with superior chemical resistance, such as:

- Polypropylene (PP)

- Polyethylene (PE)

- Polytetrafluoroethylene (PTFE, Teflon)

- Polyether ether ketone (PEEK)

-

Protective Coatings: Applying a solvent-resistant coating to the polycarbonate surface can create a barrier that prevents or slows solvent penetration.

-

Reduced Exposure: Minimizing the duration and concentration of solvent exposure is crucial. This may involve optimizing cleaning processes, using alternative cleaning agents, or implementing protective measures.

-

Temperature Control: Lowering the operating temperature can significantly reduce the rate of degradation.

-

Stress Relief: Reducing or eliminating stress on the polycarbonate part can help prevent environmental stress cracking.

Examples of Solvent Effects: a Comparative Table

| Solvent | Effect on Polycarbonate | Severity |

|---|---|---|

| Acetone | Swelling, softening, potential crazing; can cause surface damage with prolonged exposure. | Moderate |

| DMF | Significant swelling, cracking, and embrittlement; can lead to severe degradation and loss of mechanical properties. | High |

| DMSO | Similar to DMF, but potentially less aggressive depending on concentration and temperature. | High |

| Acetonitrile | Crazing and surface attack, leading to embrittlement with prolonged exposure. | Moderate |

| NMP | Very aggressive; causes rapid swelling, cracking, and potential dissolution of the polycarbonate. | Very High |

Polycarbonate and Solvents: FAQs

Got questions about polycarbonate’s resistance to solvents? Here are some answers to help clarify the key points.

What types of solvents readily damage polycarbonate?

Aromatic hydrocarbons like toluene and benzene, as well as chlorinated solvents such as chloroform and methylene chloride, severely damage polycarbonate. These solvents cause swelling, cracking, and dissolution.

Is polycarbonate plastic resistant to polar aprotic solvents?

Polycarbonate’s resistance to polar aprotic solvents, such as acetone and dimethylformamide (DMF), is limited. While it might show better resistance than to aromatic solvents, prolonged exposure or high concentrations can still lead to degradation and embrittlement. It’s always important to check specific solvent compatibility charts.

Can you use alcohol-based cleaners on polycarbonate surfaces?

Isopropyl alcohol (IPA) and ethanol can generally be used on polycarbonate for cleaning purposes. However, prolonged or repeated exposure to high concentrations might cause crazing (small surface cracks) over time. Always test in an inconspicuous area first.

What factors affect polycarbonate’s solvent resistance?

Several factors affect polycarbonate’s solvent resistance. These include the solvent type, concentration, temperature, exposure time, and the stress levels in the polycarbonate material. Understanding these factors is crucial when selecting polycarbonate for applications where solvent exposure is a concern.

So, now you know a bit more about whether is polycarbonate plastic resistant to polar aprotic solvents! Hopefully, this helped clear things up. Until next time!