Parallel Pipes: Stop Stagnation & Boost Flow!

Fluid dynamics principles govern the behavior of liquids within piping systems, influencing efficiency and performance. Reynolds number, a dimensionless quantity, characterizes flow regimes and directly impacts pressure loss calculations in networks like those managed by the American Society of Mechanical Engineers (ASME). The interaction between pipe diameter, flow rate, and fluid viscosity is crucial when considering whether a pipe parallel circuit will it cause stagnation. Furthermore, the design software used by Autodesk allows engineers to model these circuits and predict flow behavior, while practical experimentation, sometimes conducted using tools such as Pitot tubes, validates those models.

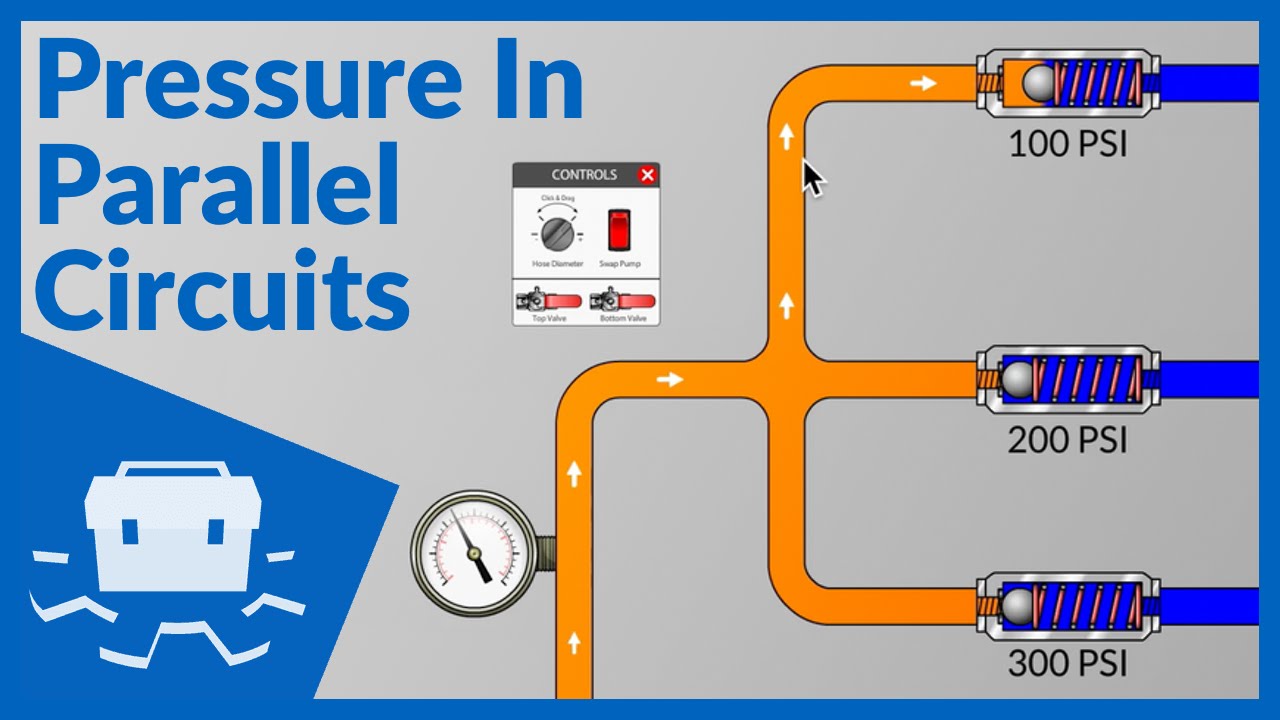

Image taken from the YouTube channel LunchBox Sessions , from the video titled Pressure in Parallel Circuits .

Understanding Parallel Pipes: Combating Stagnation and Maximizing Flow

The efficiency of a fluid transport system relies heavily on its design. One crucial aspect to consider is whether to use a single pipe or a parallel pipe configuration. The question "pipe parallel circuit will it cause stagnation" requires a nuanced understanding of fluid dynamics and system design. Let’s delve into the principles governing flow in parallel pipe systems.

The Basics of Parallel Pipe Systems

Parallel pipe systems, in their simplest form, consist of two or more pipes connecting the same two points. Instead of a single conduit, the fluid has multiple pathways to travel. This seemingly straightforward modification has significant implications for flow rate, pressure drop, and the potential for stagnation.

Why Use Parallel Pipes?

- Increased Flow Capacity: The primary advantage is an increased overall flow capacity compared to a single pipe of the same material and length.

- Reduced Pressure Drop: For the same flow rate, a parallel system typically exhibits a lower pressure drop than a single pipe, making it more energy-efficient.

- System Redundancy: If one pipe in the parallel system becomes blocked or requires maintenance, the other pipes can continue to operate, albeit at a reduced capacity, ensuring some level of fluid delivery.

Will a Parallel Pipe Circuit Cause Stagnation? Understanding the Risks

While offering numerous benefits, parallel pipe systems are not without their potential drawbacks, and the potential for stagnation in one or more of the pipes is a genuine concern. Stagnation, in this context, refers to a very low or zero flow rate in a pipe segment.

Factors Contributing to Stagnation in Parallel Pipes

Several factors can contribute to stagnation in a parallel pipe system:

-

Unequal Pipe Lengths:

- If the lengths of the parallel pipes are significantly different, the shorter pipe will offer less resistance to flow.

- Consequently, a disproportionately larger amount of fluid will flow through the shorter pipe, potentially leading to minimal or no flow in the longer pipe.

-

Differing Pipe Diameters:

- A larger diameter pipe will inherently have lower resistance to flow than a smaller diameter pipe.

- Similar to unequal lengths, this difference in resistance can lead to preferential flow through the larger pipe and stagnation in the smaller one.

-

Variations in Pipe Roughness:

- Rougher pipe surfaces increase frictional resistance to flow.

- If one pipe is significantly rougher than the others, it will experience a higher pressure drop for the same flow rate, potentially leading to stagnation.

-

Local Obstructions or Blockages:

- Partial blockages, such as debris or scale buildup, can dramatically increase the resistance in one pipe compared to the others.

- Even a small obstruction can significantly reduce flow and promote stagnation.

-

Valve Settings and Control:

- If valves are present in the parallel pipes, improper settings can create unequal resistance.

- A partially closed valve in one pipe can force the fluid to preferentially flow through the other pipes, leading to stagnation in the restricted pipe.

-

Elevation Differences:

- In systems involving liquids, elevation differences can play a significant role.

- If one pipe has a higher elevation gain than the others, the fluid will need to overcome gravity, increasing its resistance to flow.

- This is particularly relevant when starting the system after a shutdown.

Analyzing the Risk of Stagnation: Pressure Drop is Key

The core principle to understand is that the pressure drop across each pipe in a parallel system must be the same. The system automatically adjusts the flow rates in each pipe to achieve this equilibrium. Therefore, understanding how to calculate pressure drop is crucial to evaluating and mitigating stagnation risks.

Mitigation Strategies to Prevent Stagnation

Several strategies can be employed to minimize the risk of stagnation in parallel pipe systems:

- Equalize Pipe Lengths: Aim for parallel pipes of approximately equal length to minimize differences in frictional resistance.

- Use Consistent Pipe Diameters: Employing pipes of the same diameter helps ensure a more even distribution of flow.

- Maintain Pipe Cleanliness: Regular cleaning and maintenance can prevent the buildup of debris and scale, minimizing the risk of obstructions.

- Implement Flow Balancing: Install flow balancing valves in each pipe to allow for fine-tuning and ensure that each pipe carries a desired flow rate.

- Consider a Common Header System: Design the system with a common inlet and outlet header to distribute flow evenly to all parallel branches.

- Regular Inspection and Monitoring: Implement a routine inspection schedule to identify potential blockages or other issues that could lead to stagnation.

- Thermal Considerations: In systems where temperature gradients are present, insulation or heat tracing might be required to maintain consistent fluid properties and prevent viscosity changes that could affect flow distribution.

- Proper Venting/Draining: Ensure adequate venting and draining points are installed to remove trapped air or sediment which can block flow and contribute to stagnation.

Quantifying the Flow: Calculating Flow Distribution

Accurately determining the flow distribution in a parallel pipe system involves solving a system of equations that considers the pressure drop in each pipe. The Darcy-Weisbach equation is commonly used to calculate the pressure drop due to friction in a pipe:

ΔP = f (L/D) (ρV2/2)

Where:

- ΔP is the pressure drop

- f is the Darcy friction factor (dependent on Reynolds number and pipe roughness)

- L is the pipe length

- D is the pipe diameter

- ρ is the fluid density

- V is the average fluid velocity

To solve for the flow rates in each pipe, you would need to:

- Calculate the friction factor (f) for each pipe, considering its roughness and the estimated Reynolds number. (Reynolds Number = ρVD/μ, where μ is dynamic viscosity)

- Express the velocity (V) in terms of the flow rate (Q) using the relationship Q = AV, where A is the cross-sectional area of the pipe.

- Set the pressure drops (ΔP) equal to each other for all the parallel pipes.

- Solve the resulting system of equations to determine the flow rate (Q) in each pipe.

Computational Fluid Dynamics (CFD) software can be used to simulate complex parallel pipe systems and accurately predict flow distribution, pressure drops, and potential stagnation areas.

Table Summarizing Stagnation Causes and Solutions

| Cause of Stagnation | Description | Solution |

|---|---|---|

| Unequal Pipe Lengths | Significant length differences lead to unequal resistance. | Equalize pipe lengths or use flow balancing. |

| Differing Pipe Diameters | Larger diameters have lower resistance. | Use consistent diameters or implement flow balancing. |

| Variations in Pipe Roughness | Rougher surfaces increase resistance. | Use pipes with similar roughness or clean regularly. |

| Local Obstructions/Blockages | Partial blockages dramatically increase resistance. | Regular maintenance and cleaning. |

| Valve Settings | Improper settings can restrict flow in one pipe. | Ensure proper valve settings and consider flow balancing valves. |

| Elevation Differences | Gravity increases resistance in higher pipes (especially liquids). | Minimize elevation differences or account for them in the design. |

| Air/Sediment Trapped | Trapped air or sediment prevent proper flow, creating stagnation zones. | Use vent and drain valves appropriately, purging regularly and proactively. |

Parallel Pipes: Stop Stagnation & Boost Flow! – FAQs

Here are some frequently asked questions to help you better understand parallel pipe systems and how to maximize flow.

What’s the key benefit of using parallel pipes?

The primary advantage is increased flow capacity. By splitting the flow into multiple parallel paths, the overall resistance is reduced, allowing for a greater volume of fluid to pass through the system. It’s a practical way to boost flow rates without dramatically increasing pressure.

How do parallel pipes help prevent stagnation?

Properly designed parallel pipe systems ensure that flow is distributed across all branches. If one branch experiences a blockage or higher resistance, the other branches can still maintain flow, preventing complete stagnation. If the resistance is unbalanced in a pipe parallel circuit will it cause stagnation in the high-resistance pipe branch.

Is it always better to use parallel pipes instead of a single larger pipe?

Not necessarily. While parallel pipes can increase flow, factors like installation costs, space constraints, and the complexity of balancing flow need to be considered. A single, adequately sized pipe might be a more cost-effective and practical solution in some scenarios.

What factors influence flow distribution in parallel pipe systems?

The length, diameter, and material of each pipe segment significantly impact flow distribution. Maintaining uniform pipe characteristics and minimizing bends helps ensure balanced flow across all parallel branches. If those characteristics are not similar, the imbalance in the pipe parallel circuit will it cause stagnation.

And that’s a wrap! Hopefully, you now have a better handle on how parallel pipes work and why a **pipe parallel circuit will it cause stagnation**. Go forth and optimize your flow!