Liquid Oxygen Temperature: Everything You Need to Know

Understanding liquid oxygen temperature is crucial in various industries, making it a key area of focus. NASA, for instance, relies heavily on precise liquid oxygen temperature management for space shuttle propulsion. Furthermore, the cryogenic storage tanks used to contain liquid oxygen must be engineered to maintain stable temperatures, preventing boil-off. The Joule-Thomson effect, a thermodynamic process, also plays a significant role in achieving and maintaining the required low liquid oxygen temperature. These factors combined with the boiling point of oxygen, which is affected by pressure, make the control and monitoring of liquid oxygen temperature essential for operational safety and efficiency.

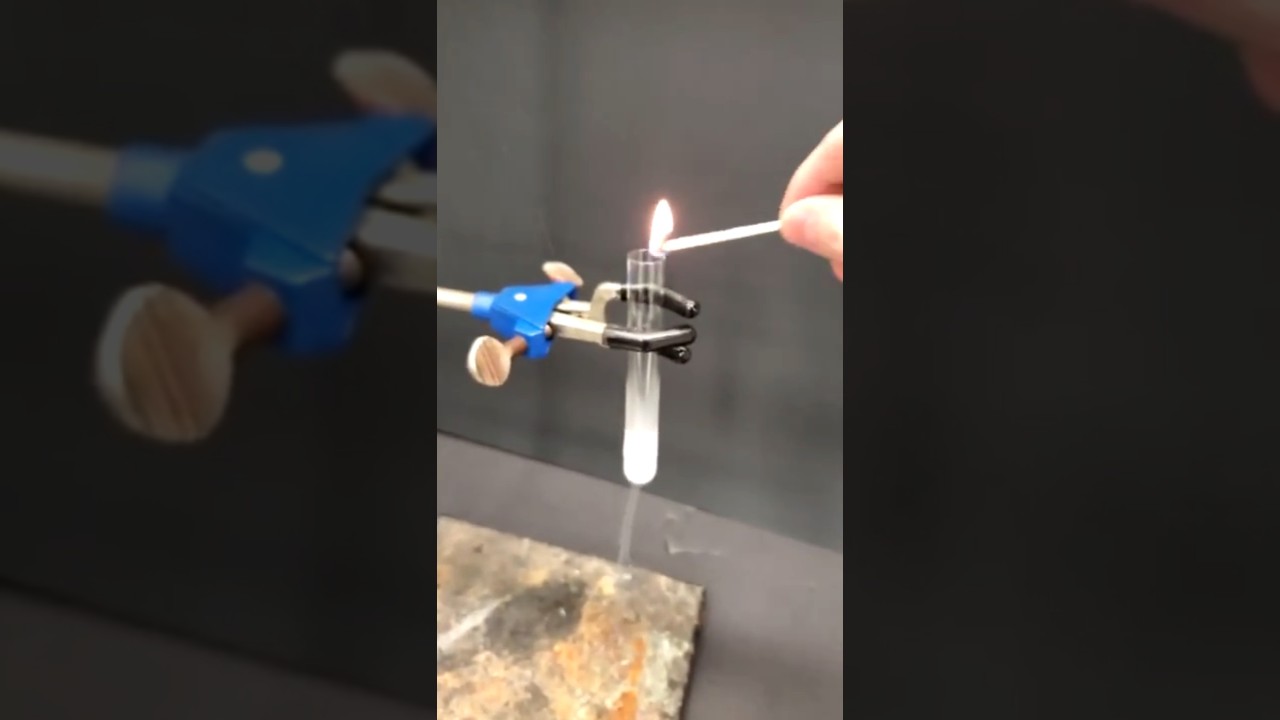

Image taken from the YouTube channel NileRed , from the video titled Dropping a match into liquid oxygen .

Liquid Oxygen Temperature: A Comprehensive Guide

Understanding "liquid oxygen temperature" is crucial across various industries, from aerospace to medicine. This guide aims to provide a detailed breakdown of liquid oxygen’s temperature properties and their implications.

Introduction to Liquid Oxygen and Its Properties

Liquid oxygen (LOx) is the liquid form of elemental oxygen. It’s a pale blue cryogenic liquid with significant oxidizing properties. Before diving into the specifics of "liquid oxygen temperature," it’s essential to grasp its fundamental characteristics.

- Cryogenic Nature: Liquid oxygen is categorized as a cryogen, meaning it exists at extremely low temperatures.

- High Oxidizing Power: Its ability to support rapid combustion makes it valuable in rocket propulsion and industrial processes, but also necessitates careful handling.

- Volume Reduction: Oxygen experiences a significant volume reduction when transitioning from gas to liquid form, enhancing storage efficiency.

Defining Liquid Oxygen Temperature

Boiling Point of Liquid Oxygen

The most crucial temperature associated with liquid oxygen is its boiling point.

- Standard Boiling Point: Liquid oxygen boils at approximately -183°C (-297°F or 90 K) at standard atmospheric pressure (101.325 kPa). This is the temperature at which LOx transitions into its gaseous state.

- Pressure Dependence: The boiling point of liquid oxygen is directly related to pressure. Increasing the pressure raises the boiling point, while decreasing the pressure lowers it. This relationship is described by the Clausius-Clapeyron equation.

Freezing Point of Liquid Oxygen

Though less commonly discussed, the freezing point of liquid oxygen represents the temperature at which it solidifies.

- Freezing Point Value: The freezing point of liquid oxygen is -218.79°C (-361.82°F or 54.36 K).

- Practical Implications: In most industrial applications, maintaining oxygen in its liquid state is the goal, so freezing is typically avoided through precise temperature control.

Factors Affecting Liquid Oxygen Temperature

Several factors can influence the "liquid oxygen temperature," requiring careful consideration in storage and handling.

- Pressure: As mentioned previously, pressure is a primary determinant. Increased pressure translates to a higher boiling point.

- Heat Input: Any external heat source, no matter how small, can cause liquid oxygen to vaporize, raising its temperature and pressure within a closed system. This is why cryogenic storage containers are heavily insulated.

- Impurities: The presence of impurities, even in trace amounts, can slightly alter the freezing and boiling points of liquid oxygen. This is especially important in research or applications requiring ultra-pure LOx.

Measurement and Monitoring of Liquid Oxygen Temperature

Accurate measurement and monitoring of "liquid oxygen temperature" are essential for safety and process control.

- Temperature Sensors: Common sensors include:

- Resistance Temperature Detectors (RTDs): Provide accurate and stable readings across the cryogenic range.

- Thermocouples: Robust and can be used in a wide temperature range, although they may require compensation for cold junction effects.

- Cryogenic Diodes: Semiconductor-based sensors specifically designed for low-temperature applications.

- Monitoring Systems: Automated systems continuously track the temperature and pressure of LOx storage tanks, triggering alarms if parameters deviate from acceptable ranges.

Practical Applications and "Liquid Oxygen Temperature" Control

Maintaining precise "liquid oxygen temperature" is critical in various fields.

- Rocket Propulsion: LOx serves as an oxidizer in rocket engines. Controlled vaporization and combustion are vital for generating thrust.

- Medical Applications: Liquid oxygen is used to provide respiratory support to patients. Precise temperature control is essential to prevent frostbite or other adverse effects.

- Industrial Processes: LOx is used in steelmaking, welding, and other processes. Temperature regulation ensures optimal reaction rates and product quality.

| Application | Temperature Control Importance | Potential Consequences of Incorrect Temperature |

|---|---|---|

| Rocket Propulsion | Ensuring consistent and efficient combustion; preventing component failure. | Loss of thrust; engine damage. |

| Medical Use | Preventing frostbite; delivering consistent oxygen flow. | Tissue damage; inaccurate dosage. |

| Steelmaking | Optimizing reaction rates; achieving desired steel properties. | Incomplete reactions; substandard product quality. |

Liquid Oxygen Temperature: Frequently Asked Questions

Here are some frequently asked questions regarding liquid oxygen and its temperature characteristics. We aim to provide clear and concise answers to help you understand this vital topic.

What exactly is the liquid oxygen temperature?

The liquid oxygen temperature refers to the extremely low temperature at which oxygen exists in its liquid state. This temperature is approximately -297.3 degrees Fahrenheit (-182.96 degrees Celsius). Reaching and maintaining this temperature is crucial for its storage and application.

Why is liquid oxygen stored at such a low temperature?

Oxygen needs to be cooled significantly to transition from its gaseous form into a liquid. This low liquid oxygen temperature allows for a much higher density compared to gaseous oxygen. This makes storage and transportation significantly more efficient.

What happens if liquid oxygen warms up?

If liquid oxygen warms up, it will begin to boil and revert back to its gaseous state. This process is called vaporization. Proper insulation and storage protocols are essential to minimize vaporization losses.

What are some of the practical applications that depend on liquid oxygen temperature?

Many applications rely on the unique properties achieved at liquid oxygen temperature. These include rocket propulsion, medical respiratory support, and industrial processes such as cutting and welding. The cold temperatures also support research in cryogenics and superconductivity.

So, there you have it! We covered a lot about liquid oxygen temperature. Hope you found it helpful and now have a better grasp of it. Thanks for reading!