Soap’s Secret Recipe: Ingredients & Their Crucial Roles!

Understanding the complex process of soap making requires a detailed examination of its fundamental components. Saponification, a core chemical reaction, highlights the necessity of carefully selected ingredients. The American Cleaning Institute offers valuable resources explaining the various substances involved. Evaluating the role of ingeredients use to make liquid soap reveals how each impacts the final product’s properties. The inclusion of additives, such as glycerin, enhances moisturizing qualities, demonstrating the interconnectedness of formulation and function.

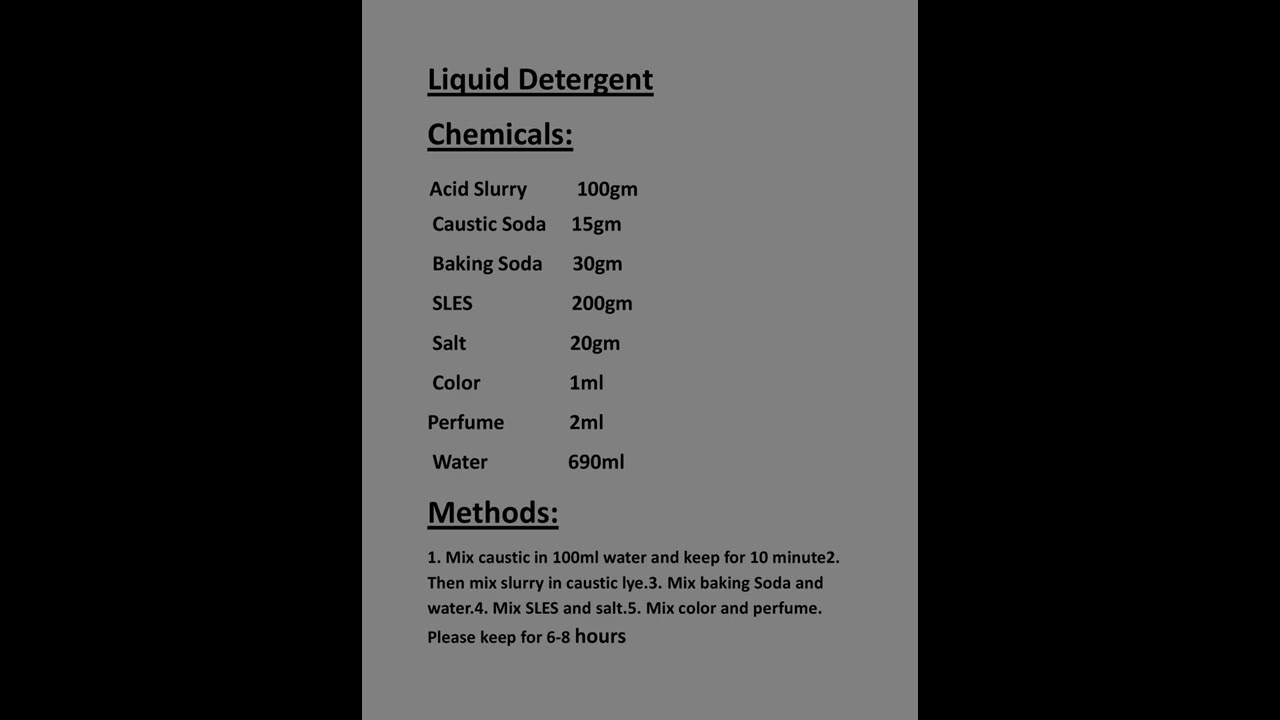

Image taken from the YouTube channel Ammar And Yousaf Chemical International , from the video titled Liquid Detergent Formulation| How to make Liquid Detergent at home #liquiddetergent #householdchores .

Soap’s Secret Recipe: Ingredients & Their Crucial Roles!

To effectively explain the "role of ingredients use to make liquid soap," we need a layout that breaks down the topic into digestible sections, each focusing on a specific aspect. This allows the reader to understand not just what the ingredients are, but why they’re used and how they contribute to the final product. The layout should prioritize clarity, organization, and a logical progression of information.

Understanding the Basics of Liquid Soap

Before diving into individual ingredients, it’s crucial to set the stage by defining what liquid soap is and how it differs from other types of soap.

- What is Liquid Soap?: Briefly explain liquid soap’s chemical composition (salts of fatty acids) and how it functions as a surfactant to remove dirt and grease.

- Liquid vs. Solid Soap: Highlight the key difference – liquid soap typically uses potassium hydroxide as the alkali, while solid soap utilizes sodium hydroxide. This difference in alkali directly impacts the texture.

The Key Ingredients and Their Roles

This section forms the heart of the article, providing a detailed breakdown of each essential ingredient and its specific function.

Base Oils and Fats: The Foundation of Soap

Base oils and fats are the primary components of soap, and their selection significantly impacts the soap’s properties.

- What are Base Oils/Fats?: Define these as triglycerides, explaining their source (plant or animal).

- Saponification: Briefly describe the saponification process: the chemical reaction between fats/oils and an alkali (lye) that creates soap and glycerin.

-

Examples and Their Roles: A table format is excellent here.

Oil/Fat Characteristics It Imparts Common Sources Coconut Oil Hard bar, bubbly lather, cleansing Coconuts Olive Oil Mild, moisturizing, gentle Olives Palm Oil Hard bar, stable lather Oil Palm Fruit Castor Oil Increases lather, adds emollience Castor Beans Shea Butter Creamy lather, moisturizing Shea Tree Nuts - Explain how different combinations of oils are used to achieve the desired balance of cleansing, lather, and moisturizing properties. For example, a soap with a high percentage of coconut oil might be very cleansing but also drying, so it’s typically combined with moisturizing oils like olive oil.

Alkali (Lye): The Catalyst for Soap Making

Lye is the indispensable ingredient that triggers the saponification process.

- What is Lye?: Define lye as an alkali (a strong base) and differentiate between sodium hydroxide (NaOH) for solid soap and potassium hydroxide (KOH) for liquid soap.

- Role in Saponification: Emphasize that lye reacts with the fats/oils to create soap. Explain that without lye, soap cannot be formed.

- Safety Precautions: Briefly mention the extreme danger of working with lye and the importance of wearing appropriate safety gear (gloves, goggles). Explain that all lye is consumed in the saponification process if performed correctly.

Water: The Solvent and Reaction Medium

Water plays multiple crucial roles in the liquid soap-making process.

- Role in Dissolving Lye: Water is essential for dissolving the lye to create a lye solution. This solution is then mixed with the fats/oils.

- Role in the Saponification Reaction: Water acts as a medium for the saponification reaction to occur. It helps the molecules of lye and fat/oil interact more efficiently.

- Role in Dilution: After saponification, more water is added to dilute the soap paste to the desired consistency.

Additives: Enhancing Soap Properties and Aesthetics

Additives are ingredients added after the saponification process to improve the soap’s performance, appearance, and scent.

- Humectants (Glycerin, Honey): Attract moisture to the skin. Explain how glycerin is naturally produced during saponification, but extra may be added.

- Essential Oils/Fragrance Oils: Provide scent. Discuss safe usage levels and potential allergens.

- Colorants (Natural Clays, Mica): Add visual appeal. Emphasize the importance of using soap-safe colorants.

- Preservatives (Phenoxyethanol, Potassium Sorbate): Inhibit the growth of bacteria and mold, extending the shelf life of the liquid soap.

- Thickeners (Salt, Guar Gum): Adjust the viscosity of the soap.

Optimizing Your Liquid Soap Recipe

This section would provide general tips and considerations for creating a well-balanced liquid soap recipe.

- Understanding SAP Values: Briefly explain the concept of SAP (Saponification) values and how they are used to calculate the correct amount of lye needed for a specific recipe.

- Considering Skin Type: Emphasize the importance of tailoring the recipe to different skin types (dry, oily, sensitive).

- Experimentation and Adjustment: Encourage readers to experiment with different combinations of ingredients and adjust their recipes to achieve their desired results. Point out that small batches may be helpful.

Soap’s Secret Recipe: FAQs

Here are some frequently asked questions about the ingredients in soap making and their importance. Understanding these components will help you appreciate the chemistry behind a good, clean lather!

What exactly is the role of lye in making soap?

Lye, typically sodium hydroxide (NaOH) for bar soap or potassium hydroxide (KOH) for liquid soap, is crucial. It reacts with fats and oils in a process called saponification. This chemical reaction transforms the fats and oils into soap and glycerin. Without lye, there would be no soap!

Can I change the type of oils to affect the final properties of my soap?

Absolutely! Different oils contribute unique qualities to soap. Coconut oil creates a hard bar with a bubbly lather, while olive oil makes a gentler, more moisturizing soap. The role of ingredients used to make liquid soap affects lather and moisturizing capabilities.

Why is it important to measure the ingredients precisely?

Accurate measurements are essential for safe and effective soap making. Too much lye will result in a harsh soap that can irritate the skin. Insufficient lye leads to a greasy soap. Consistent and careful measuring ensures the complete saponification process.

What is superfatting, and why is it beneficial?

Superfatting involves using slightly more oils than needed to react with the lye. This leaves a small percentage of unsaponified oils in the finished soap, providing extra moisturizing properties. The role of ingredients used to make liquid soap is to increase the superfat. These unsaponified oils help prevent the soap from drying out your skin.

So, now you’re in the know about the role of ingeredients use to make liquid soap! Experiment, explore, and have fun creating your own amazing formulas! Thanks for hanging out!