Approach Temperature Curve: Your Ultimate Guide [Explained]

The approach temperature curve, a critical concept in heat exchanger design, significantly influences the efficiency and cost-effectiveness of thermal processes. The effectiveness of a heat exchanger is a function of the approach temperature curve and many other related factors. Optimizing this curve, often analyzed with software like Aspen EDR, is crucial for plants following guidelines like those emphasized by the Heat Transfer Research Institute (HTRI). Understanding the approach temperature curve helps chemical engineers make informed decisions, balancing performance with capital investment to find the right approach temperature curve for their system.

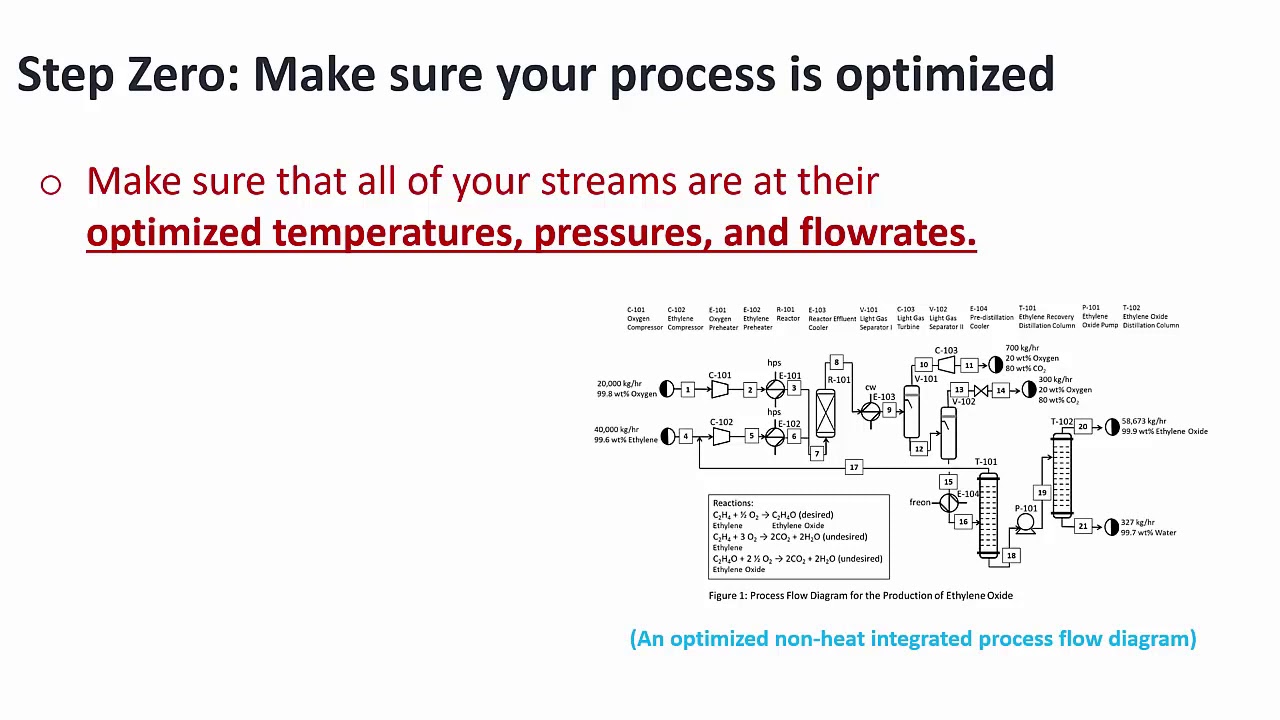

Image taken from the YouTube channel Chemical Engineering U , from the video titled Heat Integration Part 1/5: Introduction and Selecting a Minimum Approach Temperature .

In the intricate world of industrial processes, where energy efficiency and cost optimization are paramount, understanding and managing temperature dynamics is crucial. One particularly insightful concept in this domain is the approach temperature curve. It offers a window into the efficiency of heat transfer operations.

The approach temperature curve isn’t just an academic concept. It’s a practical tool with direct implications for the performance and profitability of various industrial applications.

Defining the Approach Temperature Curve

The approach temperature curve, at its core, represents the temperature difference between two fluids at the outlet of a heat exchanger or cooling tower. It specifically measures the temperature difference between the exit temperature of the cooled fluid (e.g., water exiting a cooling tower) and the wet-bulb temperature of the incoming air (in the case of cooling towers) or the exit temperature of the cooling fluid on the other side of a heat exchanger.

This difference reveals the effectiveness of the heat transfer process. A smaller approach temperature typically indicates a more efficient heat exchange. This, in turn, translates to lower energy consumption and reduced operational costs.

Conversely, a larger approach temperature suggests inefficiencies. These inefficiencies could stem from factors like fouling, inadequate flow rates, or suboptimal equipment design.

Significance in Industrial Processes

The approach temperature curve holds significance across a wide array of industrial processes:

-

Chemical Processing: Precisely controlling reaction temperatures is crucial for yield and product quality. Approach temperature management in heat exchangers ensures optimal process conditions.

-

Power Generation: In power plants, efficient heat transfer is vital for steam generation and condenser performance. Optimizing the approach temperature minimizes energy losses.

-

HVAC Systems: Commercial and industrial HVAC systems rely on cooling towers and chillers. Monitoring the approach temperature ensures efficient cooling and reduces energy consumption.

-

Petroleum Refining: Maintaining optimal temperatures throughout the refining process is essential for maximizing product output and minimizing energy usage.

Understanding the Curve: Key to Efficiency

Understanding the approach temperature curve is vital for efficient heat exchanger and cooling tower operation. It allows engineers and operators to:

-

Assess Equipment Performance: By monitoring the approach temperature, they can identify deviations from optimal performance and detect potential problems early on.

-

Optimize Operating Conditions: Adjusting flow rates, fluid properties, and other parameters can minimize the approach temperature and enhance heat transfer efficiency.

-

Reduce Energy Consumption: Efficient heat transfer directly translates to lower energy consumption and reduced operating costs.

-

Extend Equipment Lifespan: By preventing overheating and other issues, proper approach temperature management can extend the lifespan of heat exchangers and cooling towers.

Scope of This Guide

This editorial aims to provide a comprehensive understanding of the approach temperature curve and its practical applications. It will delve into the underlying principles, explore its significance in various industrial processes, and outline strategies for optimizing its performance.

Readers can expect to gain insights into:

-

The fundamental concepts of approach temperature and its relationship to thermodynamics and heat transfer.

-

The application of the approach temperature curve in different types of heat exchangers and cooling towers.

-

Strategies for optimizing the approach temperature to enhance energy efficiency and reduce operational costs.

-

Real-world examples and case studies that demonstrate the practical benefits of effective approach temperature management.

By the end of this guide, readers will be equipped with the knowledge and tools necessary to effectively manage the approach temperature in their own industrial operations, leading to improved energy efficiency, reduced costs, and enhanced overall performance.

In the intricate world of industrial processes, where energy efficiency and cost optimization are paramount, understanding and managing temperature dynamics is crucial. One particularly insightful concept in this domain is the approach temperature curve. It offers a window into the efficiency of heat transfer operations.

The approach temperature curve isn’t just an academic concept. It’s a practical tool with direct implications for the performance and profitability of various industrial applications. Now, to truly harness the power of this tool, it’s essential to dissect its fundamental underpinnings. Let’s explore the core principles that govern the approach temperature.

Fundamentals of Approach Temperature Explained

To fully grasp the implications of the approach temperature curve, it is critical to establish a firm understanding of the foundational principles that govern its behavior. These principles encompass thermodynamics, heat transfer, and the specific design considerations within chemical engineering.

Approach Temperature in Heat Exchangers and Cooling Towers: A Comparative Definition

The definition of approach temperature varies slightly depending on whether it is applied to heat exchangers or cooling towers, but the underlying principle remains the same: it’s about quantifying the effectiveness of heat transfer.

Heat Exchangers

In heat exchangers, the approach temperature is defined as the temperature difference between the outlet temperature of one fluid and the inlet temperature of the other fluid. Critically, these fluids are on opposite sides of the heat exchanger.

For example, consider a scenario where a hot process stream is cooled by water. If the water exits the heat exchanger at a temperature close to the process stream’s desired outlet temperature, then the approach temperature is low.

A low approach temperature indicates efficient heat transfer, as the cooling water has effectively extracted heat from the process stream. Conversely, a high approach temperature suggests the heat exchanger is not performing optimally.

Cooling Towers

In cooling towers, the approach temperature is defined as the difference between the cold water temperature leaving the tower and the wet-bulb temperature of the air entering the tower.

The wet-bulb temperature represents the lowest temperature to which air can be cooled by evaporating water into it. A smaller approach temperature in a cooling tower implies a more efficient cooling process, where the water is being cooled closer to the theoretical limit imposed by the ambient air conditions.

For instance, if the cooling tower achieves a cold water temperature very close to the incoming air’s wet-bulb temperature, the approach is small, and the cooling tower is considered highly efficient.

The Impact of Temperature Difference (Delta T)

Temperature difference, often denoted as Delta T (ΔT), is a cornerstone concept directly impacting approach temperature.

ΔT represents the temperature differential between two points within a system or across a heat transfer interface. In the context of heat exchangers, it’s often the difference between the inlet and outlet temperatures of a fluid.

The magnitude of ΔT directly influences the rate of heat transfer. According to Newton’s Law of Cooling, the rate of heat transfer is proportional to the temperature difference. Therefore, a larger ΔT generally drives a higher rate of heat transfer.

However, a high ΔT doesn’t always equate to optimal performance. It’s crucial to consider the system as a whole, including factors like approach temperature, to assess overall efficiency.

For instance, while a high ΔT across a heat exchanger might indicate substantial heat transfer, a simultaneously high approach temperature could suggest inefficiencies in extracting the maximum possible amount of heat.

Thermodynamics: The Driving Force

Thermodynamics provides the fundamental laws governing energy transfer and transformations, which are essential to understanding approach temperature behavior.

The First Law of Thermodynamics (conservation of energy) dictates that energy cannot be created or destroyed, only transformed. This principle explains how heat energy is transferred from one fluid to another within a heat exchanger or from water to air in a cooling tower.

The Second Law of Thermodynamics introduces the concept of entropy, stating that the total entropy of an isolated system can only increase over time. This has profound implications for heat transfer processes.

Because heat naturally flows from hotter to colder regions, the second law dictates that no heat transfer process can be perfectly efficient. There will always be some degree of energy loss or degradation, impacting the achievable approach temperature.

Understanding thermodynamic principles helps engineers design and operate systems that minimize entropy generation and maximize heat transfer efficiency, ultimately leading to lower approach temperatures.

The Role of Heat Transfer

Heat transfer mechanisms play a pivotal role in determining and influencing the approach temperature. The efficiency with which heat is transferred dictates how closely the outlet temperatures of the fluids can approach each other.

Conduction

Conduction is the transfer of heat through a solid material via molecular vibrations. In heat exchangers, conduction occurs through the walls separating the hot and cold fluids.

Convection

Convection involves heat transfer through the movement of fluids (liquids or gases). It plays a significant role on both sides of the heat transfer surface, carrying heat away from the surface or bringing cooler fluid to the surface.

Radiation

Radiation involves heat transfer through electromagnetic waves. While less significant in many industrial heat exchangers, radiation can become important at very high temperatures.

Each heat transfer mode is affected by various factors, including material properties, flow rates, and surface conditions. Optimizing these factors can enhance heat transfer efficiency and reduce approach temperature.

For instance, using materials with high thermal conductivity in heat exchanger construction promotes efficient heat transfer via conduction, contributing to a lower approach temperature.

Chemical Engineering and Approach Temperature Management

Chemical engineering design and operational choices significantly affect approach temperature management. Engineers employ various strategies to optimize heat transfer processes and minimize approach temperature.

These strategies include:

- Optimizing Heat Exchanger Design: Selecting the appropriate heat exchanger type, size, and configuration based on the specific process requirements.

- Controlling Flow Rates: Maintaining optimal flow rates of both hot and cold fluids to maximize heat transfer without causing excessive pressure drops or fouling.

- Managing Fouling: Implementing strategies to prevent or mitigate fouling on heat transfer surfaces, such as water treatment and regular cleaning.

- Process Integration: Designing processes that reuse waste heat streams to reduce overall energy consumption and improve efficiency.

By carefully considering these factors, chemical engineers can design and operate systems that achieve low approach temperatures, leading to improved energy efficiency and reduced operating costs.

Approach Temperature in Heat Exchanger Applications

Having established a firm grasp of approach temperature fundamentals, it’s time to shift our focus to the practical realm, specifically heat exchanger applications. The nuances of approach temperature become even more critical when considering the diverse designs and operational parameters of these essential pieces of industrial equipment.

Understanding the Approach Temperature Curve Across Heat Exchanger Designs

The approach temperature curve serves as a diagnostic tool, revealing the performance characteristics of a heat exchanger under various operating conditions. Different heat exchanger designs exhibit unique approach temperature profiles, reflecting their specific construction and heat transfer capabilities.

Shell and Tube Heat Exchangers

Shell and tube heat exchangers are the workhorses of many industrial processes. Their robust design and ability to handle high pressures and temperatures make them a versatile choice.

Typical approach temperature ranges in shell and tube exchangers vary widely, depending on the application, flow rates, and fluid properties. However, a well-designed and maintained shell and tube exchanger should exhibit a relatively stable approach temperature curve, indicating consistent performance.

Several factors influence the approach temperature in these exchangers:

- Baffle design and spacing, which affect flow distribution.

- Tube layout (e.g., triangular or square pitch), which impacts heat transfer surface area.

- Shell-side and tube-side flow rates, which determine fluid residence time.

Plate Heat Exchangers

Plate heat exchangers offer a more compact and efficient alternative to shell and tube designs, particularly in applications with lower flow rates and temperature differentials. Their corrugated plate design creates highly turbulent flow, promoting excellent heat transfer.

The approach temperature in plate heat exchangers is often lower than in shell and tube exchangers due to their enhanced heat transfer capabilities.

Unique design elements that affect approach temperature include:

- Plate corrugation patterns, which influence turbulence and heat transfer coefficients.

- Plate material (e.g., stainless steel, titanium), which affects thermal conductivity.

- The number and size of plates, which determine the overall heat transfer area.

The Consequences of High and Low Approach Temperatures

The approach temperature isn’t just a number; it’s a critical indicator of heat exchanger health and efficiency. Deviations from the optimal range can signal underlying problems and impact operational costs.

High approach temperatures typically indicate reduced heat exchanger performance, often due to fouling, reduced flow rates, or inadequate heat transfer area. This leads to:

- Increased energy consumption, as more energy is needed to achieve the desired temperature change.

- Reduced production capacity, as the heat exchanger struggles to meet process demands.

- Potential equipment damage due to overheating or thermal stress.

Low approach temperatures, while seemingly desirable, can also present challenges. They may indicate:

- Oversized heat exchangers, leading to unnecessary capital costs.

- Excessive cooling, potentially causing condensation or other undesirable effects.

- Instability in process control, as the system becomes overly sensitive to small changes.

Factors Influencing the Approach Temperature Curve

The approach temperature curve is not a static entity. It’s a dynamic representation of the interplay between several key factors that influence heat transfer within the exchanger.

Flow rates have a significant impact. Higher flow rates generally reduce the approach temperature by increasing turbulence and improving heat transfer. However, excessive flow rates can lead to increased pressure drop and energy consumption.

Fluid properties, such as viscosity and specific heat, also play a crucial role. More viscous fluids tend to have lower heat transfer coefficients, leading to higher approach temperatures. Fluids with high specific heat require more energy to change temperature, potentially affecting the approach temperature curve.

The heat exchanger design itself is a major determinant. The type of exchanger, its size, and its internal configuration all influence the heat transfer rate and, consequently, the approach temperature.

The Advantages of Countercurrent Flow

Countercurrent flow, where the hot and cold fluids flow in opposite directions, is generally the preferred flow configuration in heat exchangers. This arrangement allows for:

- A more uniform temperature difference across the exchanger.

- Higher overall heat transfer rates.

- The ability to achieve closer approach temperatures compared to co-current flow.

By minimizing the approach temperature, countercurrent flow contributes to:

- Reduced energy consumption.

- Increased process efficiency.

- Lower operating costs.

The Impact of Fouling on Approach Temperature

Fouling – the accumulation of unwanted deposits on heat transfer surfaces – is a common enemy of heat exchanger performance. Fouling acts as an insulating layer, impeding heat transfer and increasing the approach temperature.

As fouling progresses, the approach temperature curve shifts upward, indicating a decline in performance. This leads to:

- Reduced heat transfer efficiency.

- Increased energy consumption.

- Higher operating costs.

Regular cleaning and preventative maintenance are essential to mitigate fouling and maintain optimal approach temperatures. This involves:

- Implementing appropriate water treatment programs.

- Using mechanical cleaning methods (e.g., brushing, hydroblasting).

- Selecting heat exchanger materials that are resistant to fouling.

Approach temperature in heat exchangers paints a picture of efficiency, with lower values generally indicating better heat transfer. Now, let’s turn our attention to another critical piece of industrial equipment: cooling towers. Here, the approach temperature takes on a slightly different, yet equally important, role, serving as a key performance indicator reflecting the tower’s ability to cool water effectively.

Cooling Tower Approach Temperature: A Performance Indicator

In the realm of cooling towers, the approach temperature transcends a mere operational parameter; it becomes a vital sign, revealing the overall health and efficiency of the cooling process. Unlike heat exchangers where the focus is on minimizing approach temperature, cooling tower approach temperature provides a benchmark against which performance can be evaluated and optimized.

Approach Temperature Defined in Cooling Towers

The approach temperature in a cooling tower is defined as the difference between the cold water temperature leaving the tower and the wet-bulb temperature of the air entering the tower. It essentially indicates how close the cooling tower can bring the exiting water temperature to the ambient wet-bulb temperature.

A lower approach temperature signifies better cooling tower performance, indicating that the tower is effectively transferring heat from the water to the air.

Key Factors Influencing Approach Temperature

Several interrelated factors influence the approach temperature in cooling towers, making its analysis a multifaceted undertaking. These factors can be broadly categorized as:

-

Ambient Conditions: Ambient temperature and humidity, specifically the wet-bulb temperature, play a critical role. Higher wet-bulb temperatures inherently limit the cooling tower’s ability to cool water, resulting in higher approach temperatures.

-

Water Quality: Impurities and contaminants in the circulating water can hinder heat transfer, leading to increased approach temperatures. Scale buildup, fouling, and biological growth on fill material impede efficient evaporation.

-

Airflow: Adequate airflow through the cooling tower is crucial for effective heat removal. Insufficient airflow, caused by fan malfunctions, obstructions, or poor tower design, will raise the approach temperature.

-

Water Distribution: Proper water distribution across the fill material ensures maximum contact between the water and air. Uneven or inadequate distribution reduces heat transfer efficiency and increases the approach temperature.

-

Cooling Tower Design and Condition: The design of the cooling tower, including fill material type, tower height, and fan configuration, significantly impacts its performance. Additionally, the physical condition of the tower (e.g., damaged fill, corroded components) affects its ability to achieve optimal approach temperatures.

Strategies for Optimizing Cooling Tower Performance

Effective management of the approach temperature involves a multi-pronged approach, focusing on both operational adjustments and proactive maintenance strategies.

-

Water Treatment Programs: Implementing a comprehensive water treatment program is paramount. This includes controlling scale formation, preventing corrosion, and inhibiting biological growth to maintain optimal heat transfer surfaces.

-

Airflow Optimization: Regularly inspect and maintain fans, ensuring they are operating at their design capacity. Clear any obstructions that may impede airflow through the tower. Consider variable speed drives to adjust fan speed based on cooling load and ambient conditions.

-

Water Distribution Management: Ensure even water distribution across the fill material. Check and clean spray nozzles or distribution trays regularly to prevent clogging and ensure uniform coverage.

-

Fill Material Maintenance: Regularly inspect the fill material for damage, fouling, or scale buildup. Clean or replace the fill as needed to maintain optimal heat transfer efficiency.

-

Performance Monitoring: Continuously monitor the approach temperature and other key performance indicators (e.g., cold water temperature, flow rates) to identify trends and detect potential problems early. Establish a baseline for comparison and track performance improvements after implementing optimization strategies.

By understanding the factors that influence approach temperature and implementing appropriate optimization strategies, operators can significantly improve cooling tower performance, reduce energy consumption, and extend the lifespan of this critical equipment.

Approach temperature, therefore, serves as more than just a data point in cooling towers; it is a reflection of the delicate balance between ambient conditions, operational parameters, and design efficacy. Successfully interpreting and responding to the nuances of approach temperature is crucial for maintaining optimal cooling tower performance. We now turn our attention to practical methods of minimizing approach temperature in both heat exchangers and cooling towers, directly addressing energy efficiency in industrial processes.

Optimizing Approach Temperature: Strategies for Enhanced Efficiency

Optimizing approach temperature is not merely an operational tweak; it’s a strategic imperative for industries seeking to maximize energy efficiency and minimize operational expenditure. This requires a multi-faceted approach, blending process optimization with sound engineering principles. Successfully lowering the approach temperature leads to a tangible reduction in energy consumption and a corresponding decrease in operational costs.

Process Optimization: Minimizing Approach Temperature

Process optimization, in the context of approach temperature, involves carefully analyzing and adjusting various operational parameters to achieve the lowest possible temperature difference. This requires a detailed understanding of the specific equipment and its operating conditions.

For heat exchangers, this can involve adjusting flow rates, altering fluid properties, or modifying the heat exchanger’s configuration. In cooling towers, process optimization may necessitate adjustments to airflow, water distribution, or chemical treatment.

Effective process optimization demands continuous monitoring and analysis of performance data. It is necessary to make data-driven decisions that continually improve energy efficiency.

The Direct Correlation with Energy Efficiency

The link between optimizing approach temperature and achieving overall energy efficiency is undeniably strong. A lower approach temperature directly translates to a more efficient heat transfer process.

In heat exchangers, this means that less energy is required to achieve the desired temperature change in the process fluids. In cooling towers, a lower approach temperature means less energy is needed to cool the water to the required temperature for reuse in industrial processes.

The gains achieved through approach temperature optimization compound over time, leading to significant reductions in energy consumption and greenhouse gas emissions. These factors should be considered when making choices during this process.

Leveraging Process Engineering Principles and Tools

Process engineering principles and tools are instrumental in optimizing approach temperature performance. Design modifications can significantly improve heat transfer efficiency. For example, retrofitting heat exchangers with enhanced surfaces or switching to more efficient designs (like plate heat exchangers) can substantially reduce approach temperature.

Control system adjustments also play a vital role. Advanced process control (APC) systems can be implemented to dynamically adjust operating parameters in response to changing conditions, maintaining optimal approach temperatures under varying loads.

Computational fluid dynamics (CFD) modeling is also invaluable for simulating heat transfer processes and identifying areas for improvement. This helps optimize both design and operation.

Effective implementation of process engineering principles requires a collaborative effort between process engineers, operators, and maintenance personnel. All stakeholders must be committed to achieving optimal performance through continuous improvement.

Successfully lowering the approach temperature leads to a tangible reduction in energy consumption and a corresponding decrease in operational costs. With a firm understanding of strategies to minimize approach temperature, let’s delve into real-world examples where these principles are put into practice, showcasing the tangible benefits across various industries.

Real-World Examples: Case Studies in Approach Temperature Management

The true test of any theoretical concept lies in its practical application. Approach temperature management is no exception. Examining real-world case studies provides invaluable insights into how these strategies translate into tangible benefits. These examples demonstrate the power of optimized approach temperatures in driving energy savings, reducing operational costs, and enhancing overall system performance.

Approach Temperature Across Diverse Industries

The approach temperature curve is not confined to a single industry; its principles are universally applicable. Let’s explore its implementation across diverse sectors.

-

Chemical Processing: In chemical plants, heat exchangers are vital for heating and cooling process streams. Optimizing approach temperatures in these exchangers is critical for efficient reaction control and product yield.

For example, a large-scale ammonia plant implemented advanced control strategies to minimize approach temperatures in its synthesis gas coolers. This resulted in a significant reduction in steam consumption and enhanced plant throughput. -

Power Generation: Power plants rely heavily on cooling towers to dissipate waste heat. Maintaining optimal approach temperatures in these towers is crucial for maximizing power generation efficiency.

Consider a coal-fired power plant that upgraded its cooling tower fill material and implemented an automated water treatment system. These changes led to a substantial decrease in approach temperature, increasing power output and reducing fuel consumption. -

HVAC Systems: In heating, ventilation, and air conditioning (HVAC) systems, chillers utilize heat exchangers to provide cooling. Optimizing approach temperatures in these chillers is essential for energy-efficient building climate control.

A large commercial building retrofitted its chiller plant with high-efficiency chillers and implemented advanced control algorithms to minimize approach temperatures. This resulted in significant energy savings and reduced operating costs.

Case Studies: Quantifiable Benefits of Optimization

The real impact of approach temperature management is best illustrated through case studies that demonstrate quantifiable improvements.

Heat Exchanger Optimization: A Petrochemical Plant Example

A petrochemical plant was experiencing frequent fouling in its shell and tube heat exchangers, leading to increased approach temperatures and reduced throughput.

By implementing a proactive fouling mitigation strategy, which included regular cleaning and chemical treatment, the plant was able to significantly reduce fouling rates. This resulted in a lower approach temperature, increased heat transfer efficiency, and a 15% increase in production capacity. This highlights the importance of integrating process engineering principles for tangible results.

Cooling Tower Enhancement: A Data Center Case

A data center was facing challenges with its cooling tower performance, leading to elevated water temperatures and increased energy consumption.

By optimizing the cooling tower fan speed, adjusting the water distribution system, and implementing a more effective water treatment program, the data center was able to significantly lower the approach temperature. This resulted in reduced energy consumption, lower water usage, and improved server reliability. The ability to maintain equipment integrity and manage resources in this case are equally important.

Lessons Learned and Best Practices

These case studies underscore the importance of a holistic approach to approach temperature management.

-

Continuous Monitoring: Regularly monitoring approach temperatures and other relevant parameters is essential for identifying potential issues and implementing timely corrective actions.

-

Data-Driven Decisions: Analyzing performance data and using it to inform operational decisions is critical for optimizing system performance.

-

Preventive Maintenance: Implementing a proactive maintenance program can help prevent fouling, corrosion, and other issues that can negatively impact approach temperatures.

-

Collaboration: Effective communication and collaboration between engineers, operators, and maintenance personnel are essential for successful approach temperature management.

By learning from these real-world examples and adopting best practices, industries can unlock the full potential of approach temperature management and achieve significant energy savings and operational improvements.

FAQs: Understanding the Approach Temperature Curve

What exactly is the approach temperature in the context of heat exchangers?

The approach temperature refers to the temperature difference between the outlet temperature of one fluid stream and the inlet temperature of the other fluid stream in a heat exchanger. It’s a key indicator of heat exchanger performance. A smaller approach temperature generally means more effective heat transfer.

Why is the approach temperature curve important?

The approach temperature curve visually represents how the approach temperature changes along the length of the heat exchanger. It helps engineers identify potential bottlenecks or inefficiencies in heat transfer and optimize the design and operation of the exchanger. Understanding the approach temperature curve is vital for troubleshooting and maximizing heat recovery.

What does a very low approach temperature generally indicate?

A consistently low approach temperature across the heat exchanger suggests efficient heat transfer and good performance. However, extremely low approach temperatures might indicate that the heat exchanger is oversized for the current operating conditions or that the temperature sensors are not properly calibrated.

How does the flow rate affect the approach temperature curve?

Changes in flow rate directly influence the approach temperature curve. Increased flow rates can lead to higher pressure drops and potentially affect heat transfer efficiency, thus altering the approach temperature. Analyzing how the approach temperature curve shifts with varying flow rates can optimize the exchanger’s performance.

So, there you have it – your ultimate guide to the approach temperature curve! Hopefully, this cleared things up a bit. Now go out there and optimize those heat exchangers! Let us know if you have any questions!